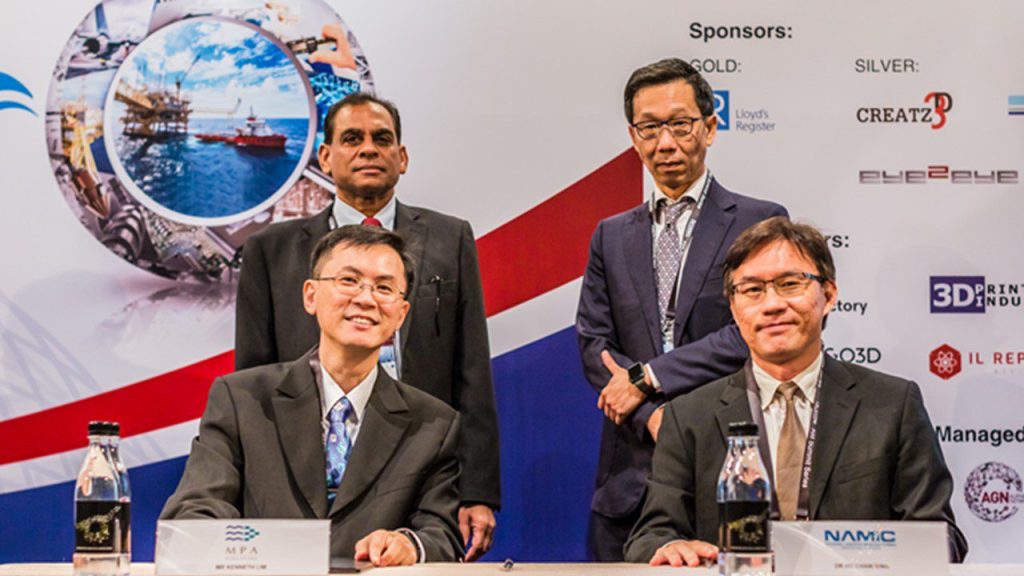

AAIS-NAMIC Joint Industry Programme on Developing Certified Components Through AM

NAMIC in partnership with Civil Aviation Authority of Singapore, Workforce Singapore, Association of Aerospace Industries (Singapore) has launched the AAIS-NAMIC Joint Industry Programme (JIP) to holistically address aviation industry technical development and training needs.