-

**Submission deadline extended to 30 June 2020**

A global competition to design an innovative rescue boat hull, leveraging the power of Additive Manufacturing.

The competition aims to encourage innovative design conceptualisation of a rescue boat hull that can be manufactured by Additive Manufacturing techniques of Wire Arc Additive Manufacturing (WAAM) or Continuous Composite Fabrication Technologies, which are seen as key game changers in the future of the naval architecture and marine engineering.

Objectives

- Develop new efficient designs for lifeboats utilising the advantages of AM to create a more compact vessel, better designed for human rescue in difficult waters.

- Utilise AM to embed sensors that allow real-time condition monitoring and can assist qualification of the vessel. Explore the use of the sensors to monitor rescued human condition.

- Ensure the design that fits inside a container and hold two persons lying down. Allow for easy transport, but also installation on larger vessels, oil platforms and deployment in near shore rescue.

- Install autonomous systems on the lifeboat that eliminate the need for manned rescue. The vessel must able to withstand dangerous North Sea conditions.

- Develop a method to qualify the vessel within regulatory constraints to ensure the vessel is safe and sea-worthy.

Prizes

- 1st Prize: S$30,000

- 2nd Prize: S$20,000

- 3rd Prize: S$10,000

- Winning design(s) will be considered by sponsors for further refinement and manufactured using the WAAM or Composite CFM process.

- Opportunity to be part of the pioneering team to design and produce an Additively Manufactured marine craft.

Rules and guidelines

Regulatory

- Comply with the LSA (Life Saving Appliance) code, SOLAS (Safety Of Life At Sea) and Singapore Flag State requirements as deemed appropriate. Deviation is allowed for innovation to happen.

- Rescue boats shall not be less than 3.8 m and not more than 8.5 m in length

- The regulations require the capability for a stretcher and seating for 5 people

- Must have power for 4 hours continuous operation and must have a minimum speed of 8 knots

- A rescue boat must be able to operate in Beaufort 6 sea states and there are rare cases where the use of a crew is a significant additional risk (maybe situations such as a large acid/chemical spill).

Design

- Hull design shall be scalable to account for different number of people saved, 2 and 3. As a minimum, the design should accommodate one person lying flat

- Propulsion and control surfaces be reasonably covered and shall not pose any danger to humans during the entire recovery operation phase

- Hull design should be reasonably buoyant and self-righting to withstand distressed perturbations as the person climbs on-board the vessel.

- Top-side design shall take into account perception and localization sensor installations to support autonomous homing towards any person-in-water. The design shall allow for mounting of the specified sensor mast for autonomous operation. – ST to provide info on autonomous mast: mounting specifications etc.

- The vessel shall have necessary compartments to store life-saving equipment, rations and drinking water to sustain 2 persons for up to three days.

- The vessel must be quickly and easily deployed and recoverable. Conventional davit systems will be used.

- Designers are encouraged to take advantage of the design freedom and advantages that additive manufacturing techniques allow.

- The vessel is intended to be class certified after manufacture

Performance Requirements

- Shall ensure safe transfer of person in water under dynamic conditions;

- Shall protect the persons in water against risk of injury from impact with the vessel’s side or other structures;

- Shall be designed for rescue persons incapacitated.

- Shall ensure that persons in the water can be simply secured, and prevented from dropping or sliding out of the craft after rescue due to dynamic motions;

- Shall be of sufficient strength to enable safe recovery to parent vessel when fully loaded with causalities;

- Shall have a launching time not more than 5 minutes ;

- The craft shall be self-draining and shall have a freeboard of 30 cm.

Manufacture

- The vessel can be constructed using Wire Arc Additive Manufacturing or Composite Continuous Fibre Manufacturing.

- Vessel will be class certified after manufacture.

Wire Arc Additive Manufacturing

- Utilising aluminium as the deposition metal.

- Thickness limitation on a WAAM only finish (non-machined) is 5mm thick

- Tolerances are 0.1mm.

- No limitations on curvature, however there is a limitation on the build direction of 45 degrees either side of vertical. Although a rotatable jig may also be utilised to reduce any further limitations.

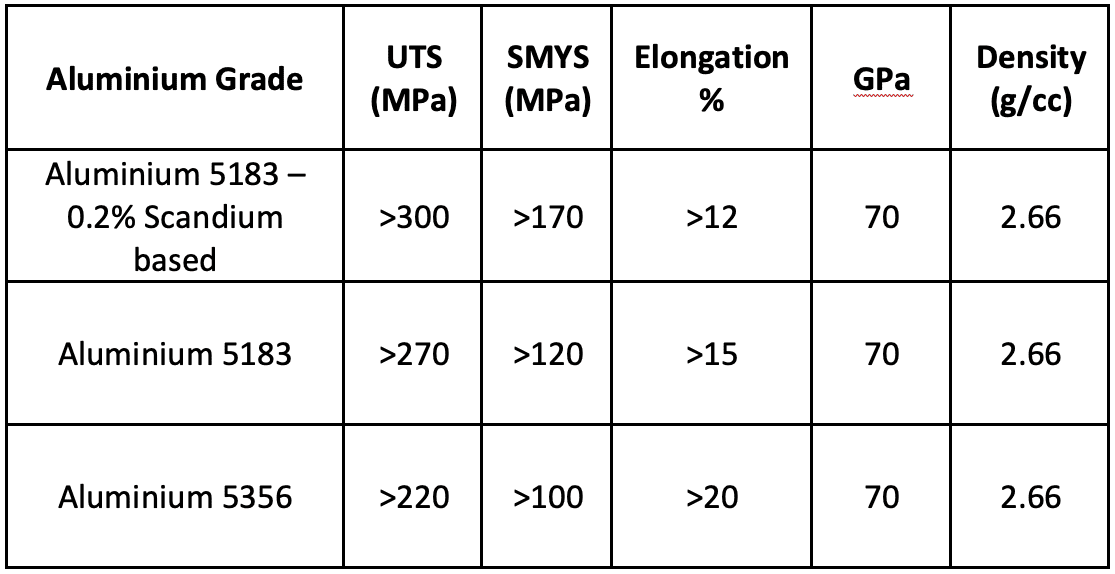

- Material Specifications of WAAM Aluminium:

Composite Continuous Fibre Manufacturing

- Utilising different grades of fibreglass in a polymer matrix. The Process deposits a unidirectional fibre, Mechanical properties depend on the fibre orientation.

- Mass deposition rate is dependent on fibre size and complexity of path:

- 600TEX:: Fibre section width: 1.4mm, layer height : 0.4mm. (max 400 g/h)

- 1200TEX: Fibre section width: 2.5mm, layer height: 0.5mm. (max 800 g/h)

- 2400TEX: Fibre section width: 4.2mm, layer height: 0.6mm. (max 1600 g/h)

- No Thickness limitations. Fibres can be used together to reach desired size

- Minimum curvature is double of fibre width. Minimum extrusion length of 20mm.

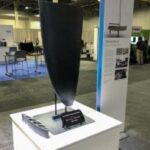

Examples of maritime AM projects

- Additive Manufacturing at Lloyd’s Register

- Composite AMfg

- Autodesk-Nasa lander AMfg

- Autodesk-European project for huge hybrid Mfg (applicable for boat additive mfg as the vessel is of very large scale

- Autodesk-Ramlab

- Other resources

Submission

- The design should be submitted to namic via email [ [email protected] ] by 30 June 2020 with the following details in English:

- Registration form [download link]

- Files in industry standard formats

- Incomplete submissions will be disqualified

Design Submission Requirements

- Submitted designs should include:

- General Arrangement plan (to include principal particulars)

- Transverse sections structural plan (to include typical connection details)

- Operational Envelope of intended speed and sea state (if intended to exceed the minimum specified requirements)

- Additional information which would be beneficial if available:

- Longitudinal profile structural plan

- Deck structural plan (if applicable)

- Note that structural plans are to include all plate / laminate thicknesses and dimensions.

Terms and Conditions

- All entries must be participants’ original work, have not been in production or otherwise previously published or exhibited.

- The design including picture, icon, symbol within, shall not in any way infringe any third party’s right, including but not limited to copyright, logos, trademark, or other proprietary rights.

- Team entries are welcome. If a team wins, there will be only 1 prize per team and the cash prize will be transferred to the team leader, who will be solely responsible for the distribution of prize among team members.

- The participants will retain the IP related to their hull design.

- Winning designs will be mentioned and showcased during engagements, demonstrations, displays and interviews pertaining to the subject.

- The winner or a representative from the winning team must be present in person to collect the prize in Singapore at the prize giving ceremony.

Eligibility

- Employees of sponsoring organisations are not eligible to participate.

- Participants can be from Marine engineering or naval architecture design bureaus, independent conceptual/ industrial designers, naval architects and engineers, institutional researchers, designers.

Judging Criteria

- Judging criteria will be based on the compliance with requirements, design innovation, extent to which AM enabled design freedoms are exploited and manufacturability, such as:

- Innovation of design, including degree to which AM enabled design freedoms are exploited

- Practicality and manufacturability of the design

- Compliance with regulatory and design requirements

- Shortlisted entries are required to be presented to the panel of judges. This may also be over video call.

- Panel of judges includes industry experts.

- Results will be announced 4 weeks after the judging day.

- The decision of the jury will be final.

- The organiser reserves the right to amend these rules at any time. Any amendment to competition rules will be announced.

Resources available to participants:

- Consultation with relevant technical experts is available upon request. Please email us [ [email protected] ] for any questions related to the competition or specific technical consultation requests.

Software Resources

- Autodesk design, simulation and manufacturing software tools and packages may be made available to the participants for the duration of the competition, upon request.

Contact Information

- Please email [email protected] for all questions, submissions and requests for software or expert consultation, and we shall liaise with you personally.

- Entry submission deadline extended to 30th June 2020.

-

-