ST Engineering is a global technology, defence and engineering group with offices across the Asia Pacific, Europe, the Middle East and the U.S, serving customers in more than 100 countries. The Group uses technology and innovation to solve real world problems and improve lives through its diverse portfolio of businesses across the aerospace, smart city, defence and public security segments. Headquartered in Singapore, ST Engineering ranks among the largest companies listed on the Singapore Exchange. Please visit www.stengg.com for more information.

ST Engineering made its first foray in Additive Manufacturing (AM) in 2014 with the acquisition of Stratasys Fortus 900MC and EOS M280 systems. Confident that AM is the way forward, ST Engineering collaborates with technology partners and like minded customers to develop innovative solutions in the field.

In recent years, ST Engineering has been steadily building its virtual inventory of airworthy parts to enhance customers’ aircraft operations.

We are a one-stop solution provider for AM. With our rich experience in engineering design, quality-assured print processes and materials, post-processing know-how, and certification network, we can turn an idea from concept to product seamlessly and sustainably.

Our diverse AM portfolio ranges from airworthy components to non-aircraft parts, including:

- Cabin interiors

- Freighter components

- Brackets and fittings

- Passenger-to-Freighter components

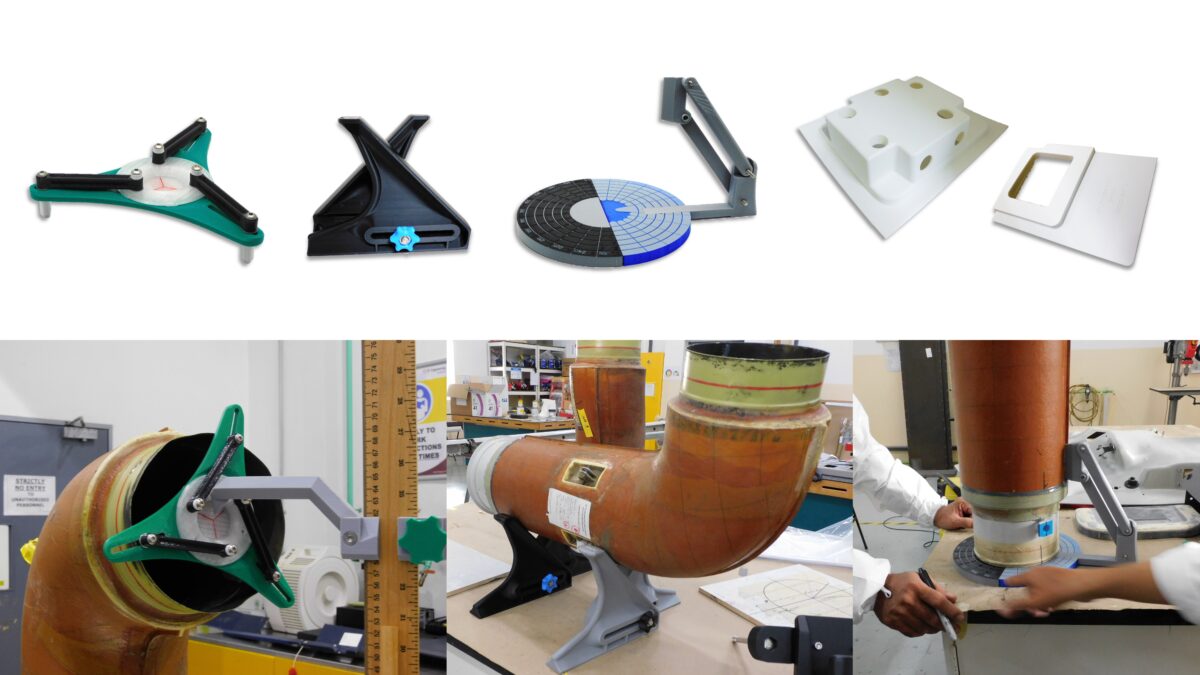

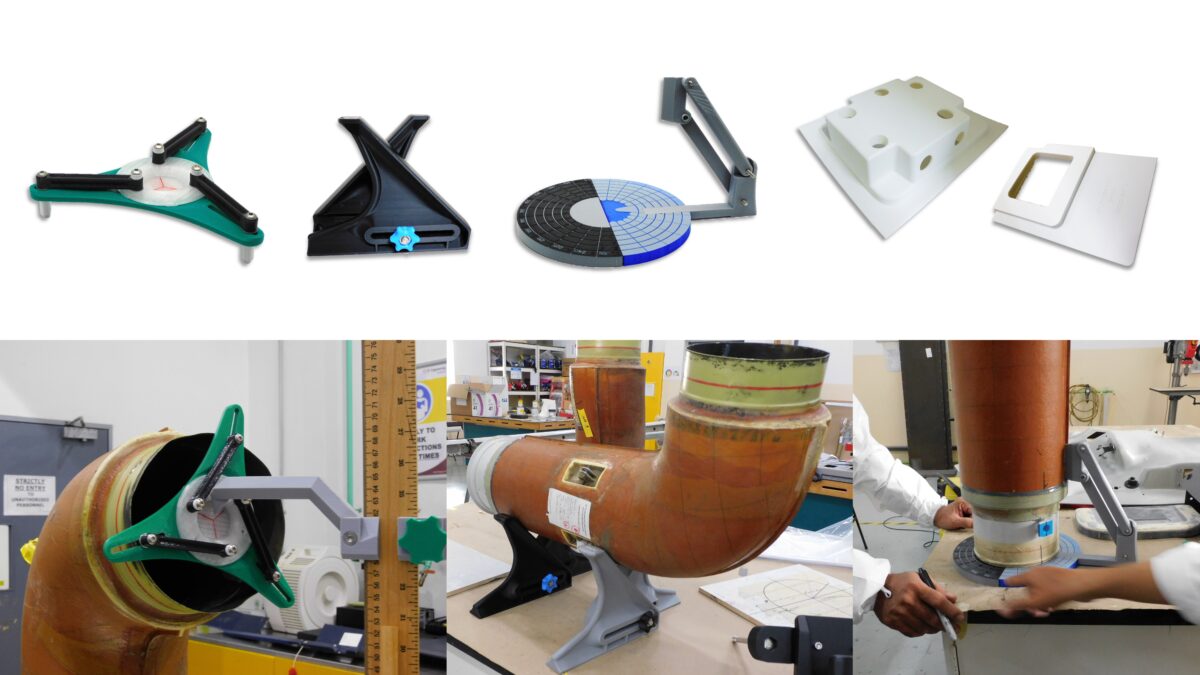

- Jigs, tools, and fixtures

- Customised parts

- Lightweight aluminium solutions for diverse industries

We have end-to-end capabilities, including:

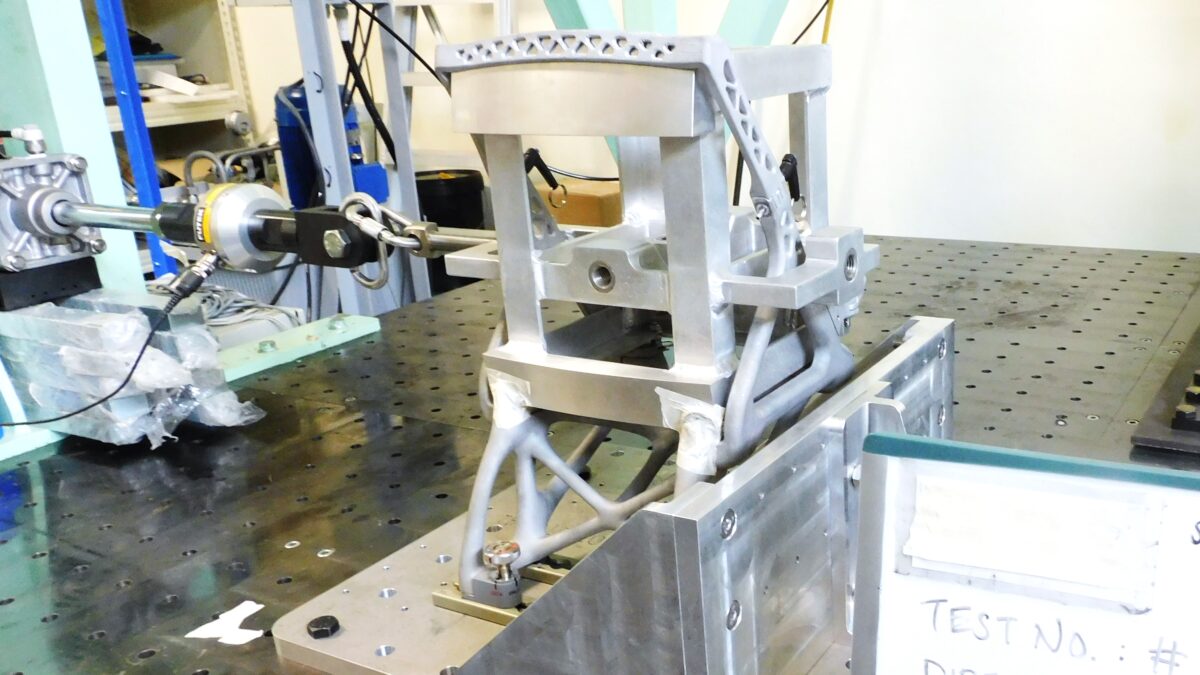

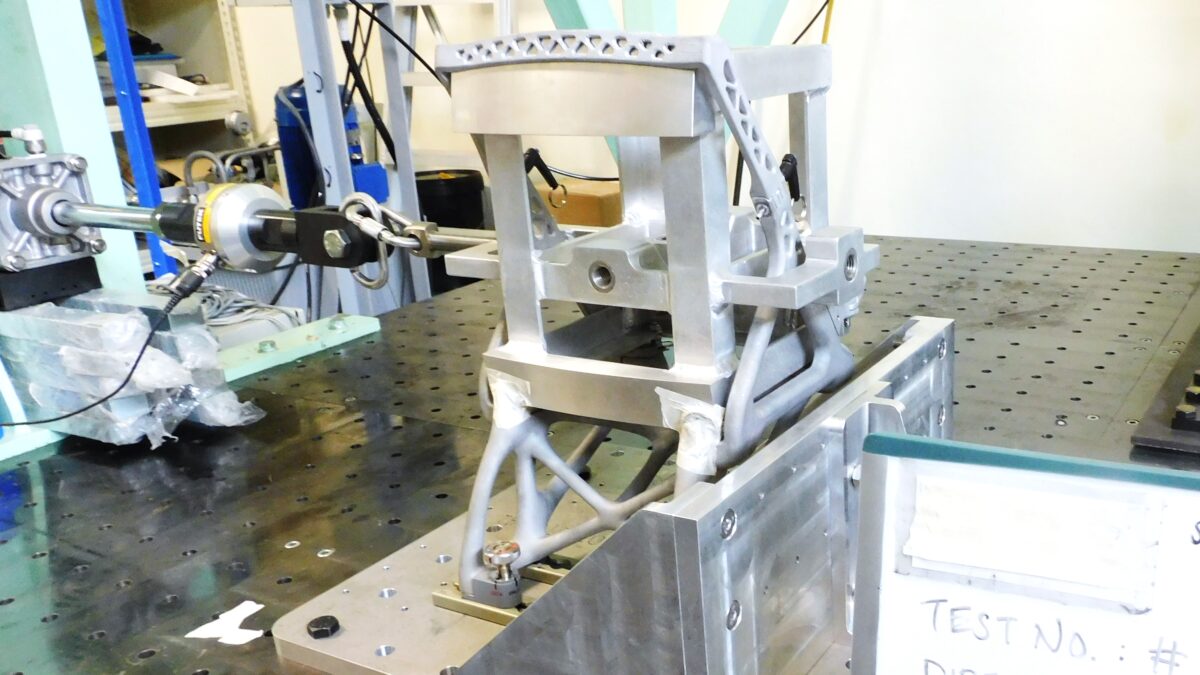

- Design optimisation via topology optimisation and design improvements

- Print optimisation via part nesting and print orientation

- Proprietary process specifications accepted by EASA and CAAS

- Post-processing know-how and network

- Certification privileges and track record

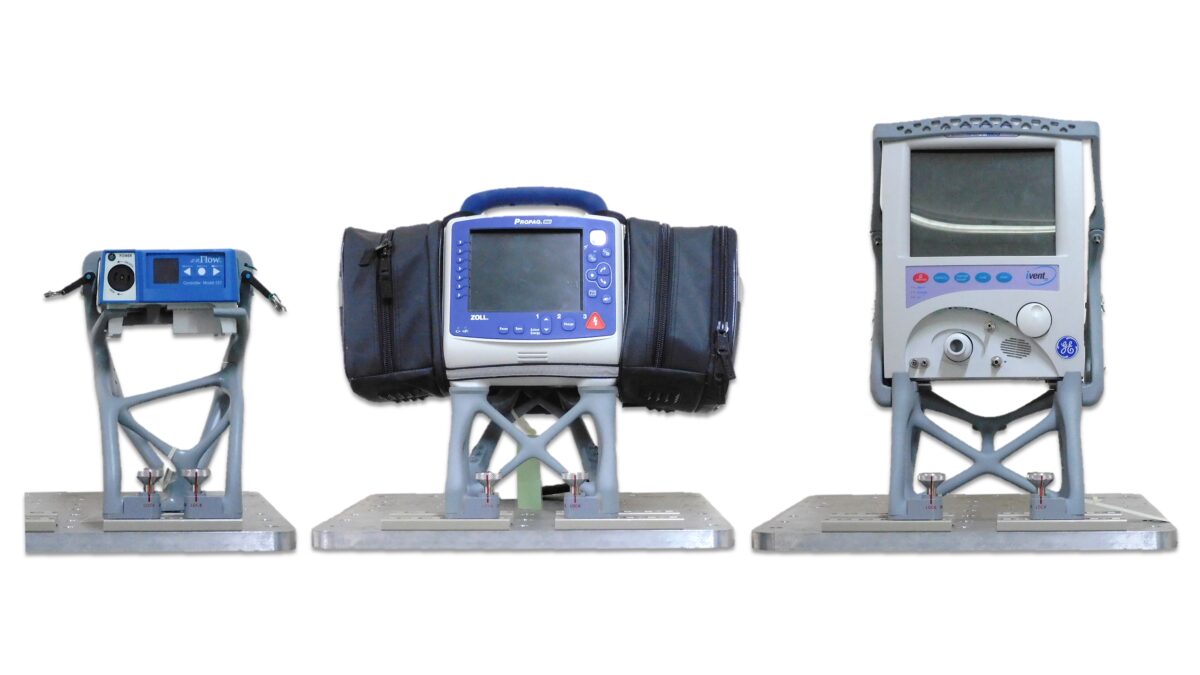

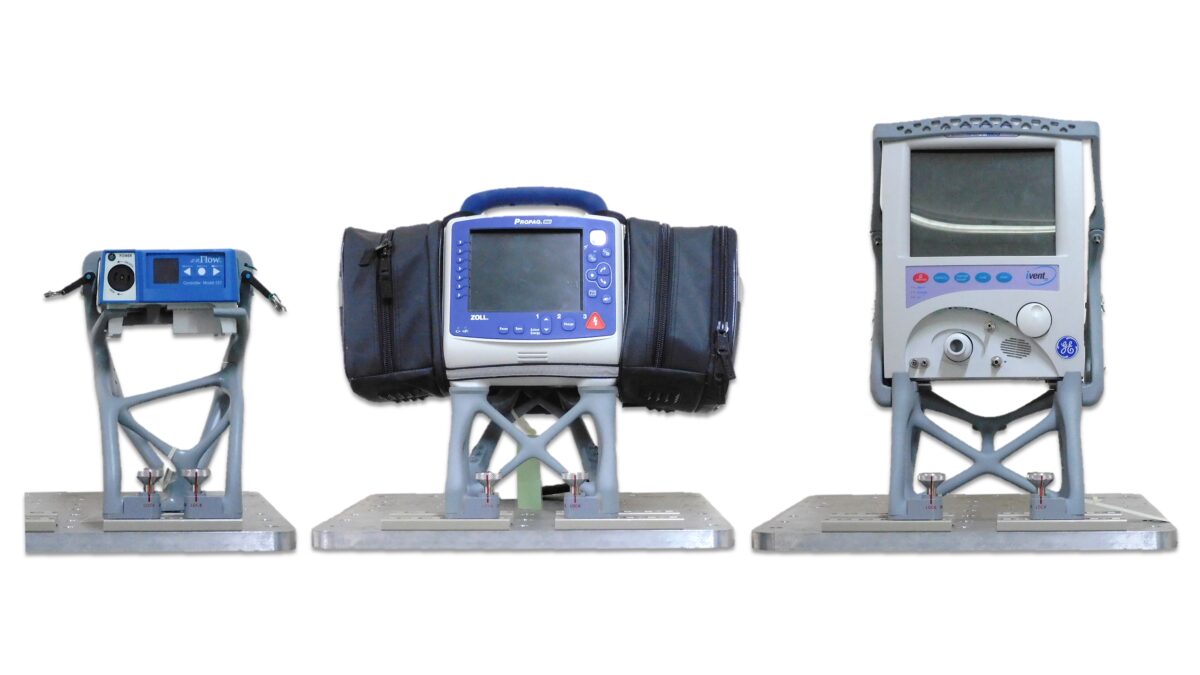

1. We produce a variety of certified parts for diverse industries using qualified systems and materials. |

2. We harness AM technologies to produce customised optimised parts to customers for an operational boost.

|

3. We perform a variety of tests and simulations on printed components to ensure their uncompromised quality and performance consistency.

|

4. Our robust AM post-processing methodologies range from corrosion protection and painting for metal parts to smoothening processes to meet aesthetic and finishing requirements.

|

5. Apart from aircraft parts, we also produce tools, jigs, and fixtures for maintenance and modification process improvements. |

Our qualified systems and materials include:

- Fortus 900MC FDM system with ULTEM 9085 PEI/PC based engineering polymer

- EOS P396 PLS system with PA2241FR fire retardant nylon

- EOS M290 DMLS system with AlSi10Mg aluminium alloy

Printing capabilities: