Spare Parts 3D has for mission to facilitate the adoption of Additive Manufacturing in industries.

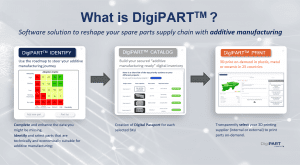

Spare Parts 3D has developed DigiPARTTM, a unique end-to-end software solution which enables customers to apply additive manufacturing to their spare parts and reduce obsolescence, lead time, minimum order quantity, and inventory levels.

DigiPARTTM offers a road map to adoption of AM by looking at the entire flow: Identification, Cataloguing and Printing.

DigiPART – IDENTIFY

DigiPARTTM is a powerful Machine Learning based software that allows the automation of parts. Spare Parts 3D offers what is probably the most efficient way to identify the spare parts in your warehouse that are 3D printable. With your data and our AI based DigiPARTTM software, we can identify the parts that are technically 3D printable and those that make most business sense.

The output is an Adoption Matrix which should be looked at as a key iterative decision tool to focus resources on the parts that have highest feasibility and attractivity results. Each part has a recommended technical 3D solution and corresponding business case.

DigiPART – CATALOG

The software will guide customer and manage a workflow to build a digital passport. It will help him define the content of passport in addition to material and printing process such as 2D, 3D, Bill of Material including certification and qualification documents. Upon review and validation, data is then set into part digital passport (structured, secured, traceable) and added to the customer’s digital catalog.

With this digital passport, customers are then able to produce their spare parts on-demand with DigiPART PRINT right the first time.

Printing Technologies:

FDM

SLS

SLA

MJF

Applications:

FDM & SLS – Face Shields

FDM – Face Masks, Mask stress relief band

MJF – Ventilator components

SLA – Nasal Swabs (under approval), oxygen splitters

SLS – door handles

Materials availability:

– SLA: bio-compatible resin

– FDM: ABS

– SLS & MJF: Pa11 and Pa12 (biocompatible)

Capacity per day:

Reusable Face Shield: up to 5000

Door Handle: up to 450

Face masks: up to 800

Ventilator components: up to 200

Nasal swabs (under approval): up to 5000

Oxygen splitters: up to 800

Certifications: ISO 9001