Dassault systemes is a leading software company, offering business solutions on the 3DEXPERIENCE.

The 3DEXPERIENCE platform is a business experience platform. It provides software solutions for every department in your company – from marketing to sales and engineering – that help you in value creation and differentiating customer experiences. With a single, easy-to-use interface, it powers industry solution experiences, in a collaborative interactive environment (on premise and in public or private cloud).

Digital Thread for Additive Manufacturing

Dassault Systèmes offers a full portfolio of integrated applications for additive manufacturing that connect across multiple disciplines – design, manufacturing and simulation.

The 3DEXPERIENCE platform provides a rich set of applications identified within these key themes:

3DEXPERIENCE Marketplace

The most seamless way to get your parts made and collaborate with leading digital manufacturers worldwide.

In-Silico Material Engineering

Materials are core to any additive process – from first principles using molecular dynamics/quantum mechanics to any materials research for additive, whether polymers or metal alloys.

Function-driven Generative Design

Our function-driven design tools, backed by multiphysics simulation-based optimisation and predictive analytics, have led to a new design practice for innovation.

Process Design & Production Plan

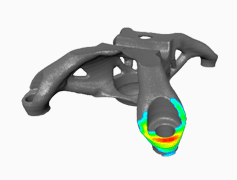

Print to Perform focuses on the core theme of Virtual Printing, our powerful general purpose framework for simulating additive manufacturing processes, materials and scales.

Our virtual printing solution delivers the following key capabilities:

– Accurate, validated and reliable solutions

– Inherent strain and full thermal-mechanical solutions

– Micro-structure predictions, as-built material properties, and residual stresses

– Failure predictions, process induced (crack initiation and growth) or machine induced (recoater collisions)

– Post-processing effects: build plate removal and heat treatment

– In-service assessment and fatigue life predictions of manufactured parts