The Advanced Remanufacturing and Technology Centre (ARTC) is a contemporary platform built upon strong public-private partnerships. The ARTC is led by the Agency for Science, Technology and Research (A*STAR), in partnership with the Nanyang Technological University, Singapore (NTU Singapore).

ARTC has a membership consortium with over 80 members, ranging from global multinational corporations (MNCs) to small and medium enterprises (SMEs). ARTC focuses on advanced manufacturing and remanufacturing and serves to accelerate the transfer of innovation from applied research to industrial applications.

Core technology themes at ARTC are Additive Manufacturing Industrialisation, Advanced Remanufacturing, Data-driven Surface Enhancement, Advanced Robotic Applications, Intelligent Product Verification and Smart Manufacturing.

Key AM technologies available at ARTC include Powder Bed, Powder Blown, Cold Spray and Hybrid, among various others for metal, polymer and ceramic process-ability.

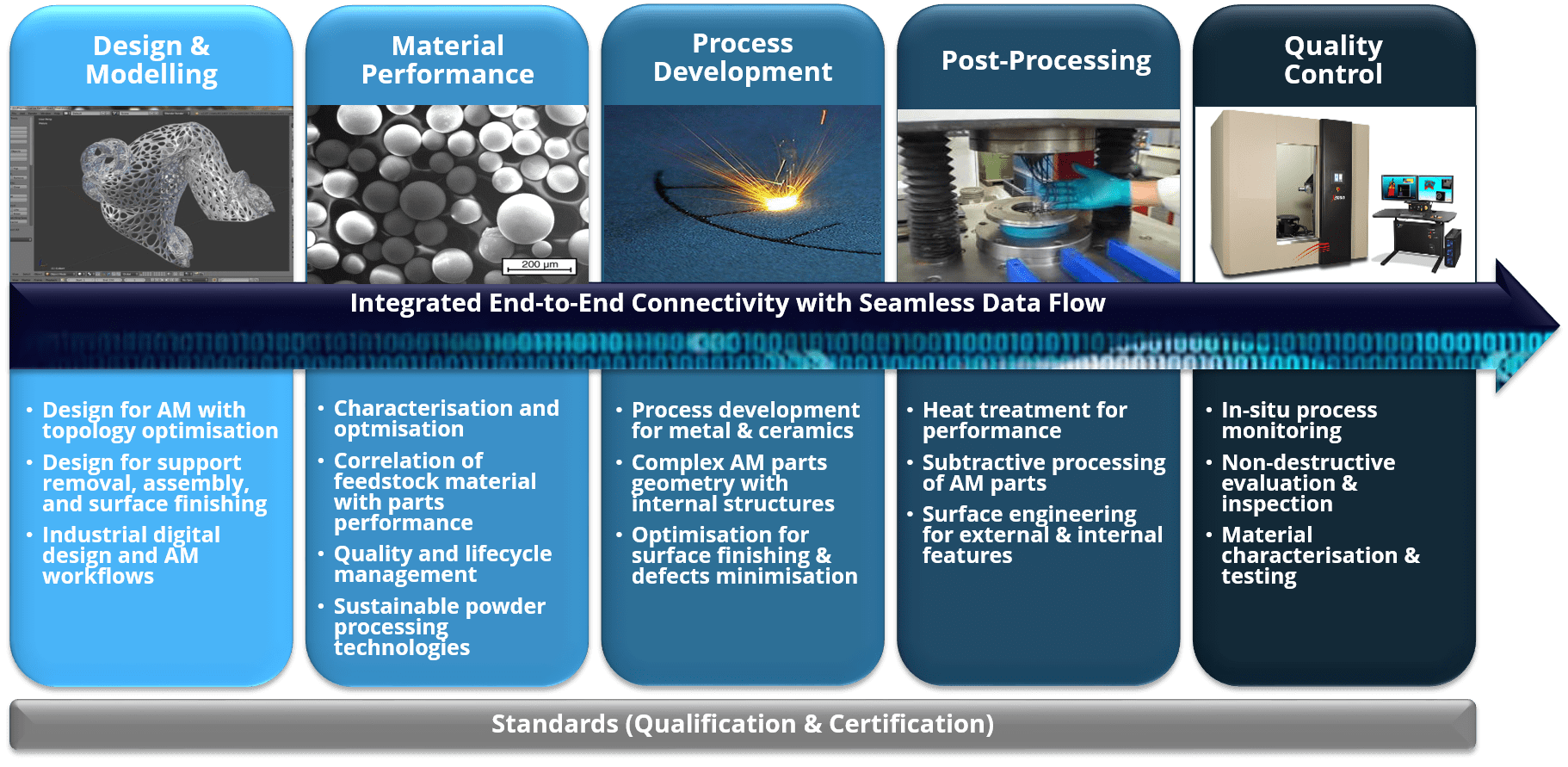

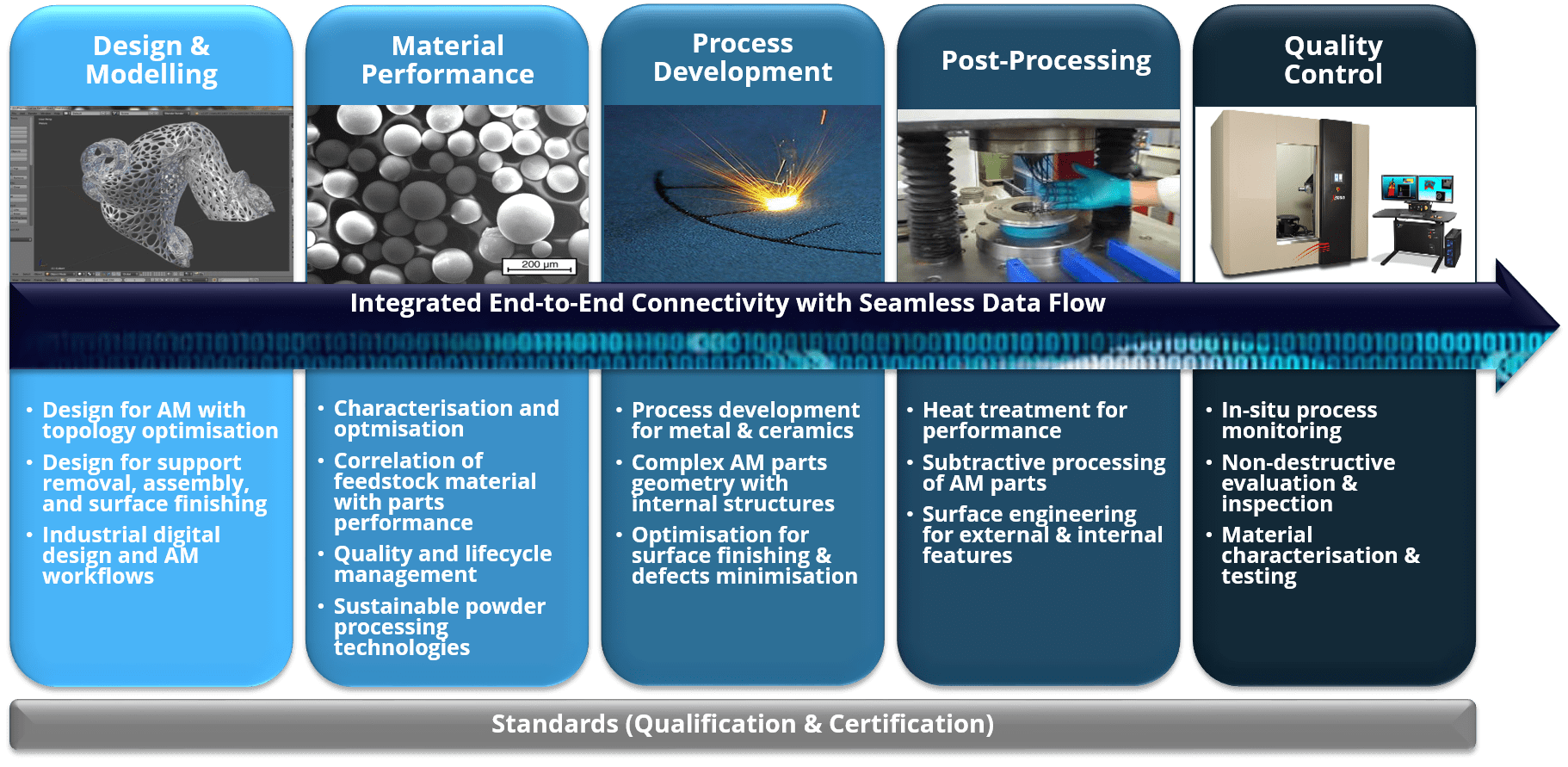

ARTC delivers complete solutions from pre to post additive manufacturing processes, in order to enable test bedding of the manufactured components and translation into product-ready solutions.

- In-situ Process Monitoring

- Process Parameter Development

- X-ray CT Inspection

- Post-Processing Solutions

- Integrated End-to-End AM supported by PLM-MES and Qualification Framework

- Unified Factory 4.0

More information on Additive Manufacturing Post Processes can be found here: AM Post-Processing Brochure (DSE)

Printing Technology:

1) SLA

2) FDM

3) Metal LPBF

4) Controlled Atmosphere and Hybrid Laser Metal Deposition

5) Other areas:

a) Design

b) Materials

c) AM process development

d) Post processing

e) Inspection & Quality Control

Applications:

1) SLA – Ventilator parts, jig for mask manufacturing, adapters for repurposing of alternate masks eg. snorkeling masks

2) FDM – Face mask, face shield visor, ventilator parts, jig for mask manufacturing, adapters for repurposing of alternate masks eg. snorkeling masks

3) Metal LPBF –Spare parts for ventilator systems, indirect printing (tool mould for making medical grade polymer parts)

Materials:

SLA – Clear Photopolymer Resin

FDM – ABS, Nylon, ULTEM

Metal LPBF – SS316L, SSCX Ti6Al4V and Maraging steel MS1

Capacity / month:

SLA – face shields (100)

FDM – face shields (400)

Metal LPBF – small spare parts (100-300), large metal parts (10 – 15)

Contact:

Christopher Mason

M: +65 9359 5209

christopher_mason@artc.a-star.edu.sg

3 Clean Tech Loop, Cleantech Two, #01-01, Singapore 637143

www.a-star.edu.sg/artc