Bralco Advanced Materials is a deep-tech R&D & Product Development SME based in Singapore engaged in developing electromagnetic components for electric motors from soft and hard (rare earth) magnetic materials using state of the art Laser Powder Bed fusion (L-PBF) process of Additive Manufacturing.

Processing Rare Earth Based Magnets with Additive Manufacturing

In line with their R&D goals, Bralco is currently researching on processing Rare Earth based permanent magnets with Additive Manufacturing (AM). Rare Earth based permanent magnets exhibit exceptional magnetic performance that can be used in motors, generators and other electronic applications. At present, these materials are not able to be processed with AM or 3D printing technologies.

By engaging AM processing, companies can now use these Rare Earth materials in rapid prototyping while reducing material waste, producing products with complex geometries and enabling part consolidation. This can open doors to new applications such as in electric motors with complex design features.

Bralco foresees challenges in utilizing AM printing technologies due to the traditional metal composition of Rare Earth materials, and they plan to work closely with their material manufacturing partners in tuning the chemical compositions such that they are suitable for AM process technologies.

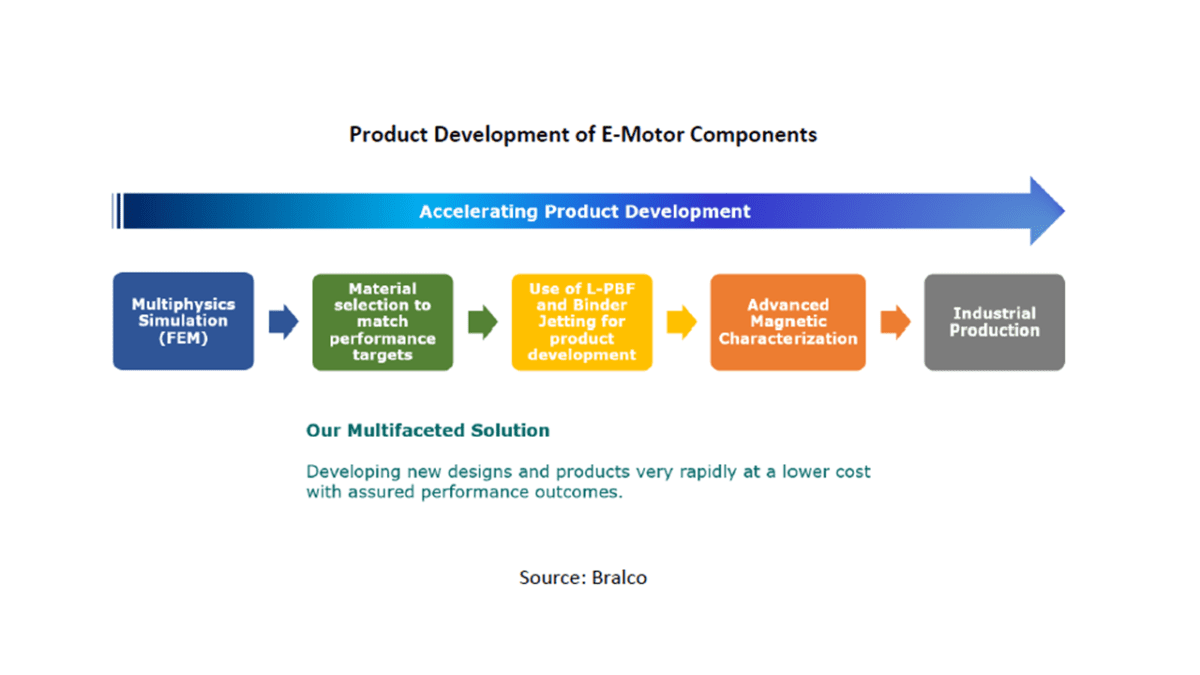

“AM technology is an ideal way to rapidly experiment with alternative material compositions with the least material wastage, zero investment in dies and molds, shortest time from powder to part and lowest prototyping cost. The binder jetting process of AM also offers a clear path towards producing at scale and at an economically viable cost structure,” shared Mr Amit Nanavati, CEO and Founder of Bralco Advanced Materials.

Besides utilizing AM to conduct R&D on Rare Earth based permanent magnets, Bralco is also looking into applying AM to produce the powertrains for electric vehicles (EV), the set of components that converts the engine’s power into vehicle movement. Parts that can be additively manufactured include the fabrication of stator, rotor, permanent magnets and copper wirings [1].

Landscape of Electric Vehicles in Singapore

EVs have yet to be widely adopted in Singapore as they are known to be expensive, with the population of EVs on the road estimated at 1,125 as of January 2020 [2]. However, with the green benefits of EVs, and Singapore’s goal of phasing out internal combustion engine vehicles by 2040, the government is accelerating its efforts to encourage EV adoption. Such efforts include the EV Early Adoption Incentive (EEAI) where rebates are provided to buyers of EVs. In addition, plans are underway to increase the number of electric charging stations to 28,000 by 2030.

Cost Benefits of AM in Producing Electric Vehicles

The cost of an electric car is relative to the cost of the batteries and the powerdrive system. A major component of the powerdrive is the electric motor and there are also traction (hub) motors used in the wheels of the vehicle. The traditional fabrication processes of making stators, rotors and permanent magnets generate substantial material wastage which can be reduced to a negligible amount by adopting AM technology. There is a further advantage of incorporating topology optimization and multiphysics simulation within the Design for Additive Manufacturing process to reduce the number of experiments necessary to reach optimum performance. All these add up to lowering the part cost substantially and contribute to the reduction in the electric vehicle cost as the powertrain contributes about 45% of the cost of the vehicle.

Bralco is focusing their efforts in the next few years to optimize additively manufactured soft and permanent magnets and magnetic components. It also plans to scale its commercialization plans by setting up Application Engineering Centres in India, China and Canada to bring the technology closer to the EVs’ motor and powertrain system developers in the aforementioned countries. In partnership with NAMIC and supported by Enterprise Singapore, Bralco’s has since established an AM R&D centre in Singapore for optimizing AM technology for their permalloy EV products. It was awarded the EUREKA GlobalStars Research Grant in Singapore’s inaugural partnership with EUREKA. EUREKA is an intergovernmental network of 41 member states that supports market-oriented research and development, in order to drive innovations and cross border collaborations.

NAMIC partners with the academia and government agencies such as Singapore Economic Development Board, Enterprise Singapore, and A*STAR to provide funding and support to industry collaborators who wish to explore Additive Manufacturing in their respective business domains. In addition to funding, NAMIC assists their collaborators in initiating, executing and commercializing their technology while also offering them market exposure and investor leads. For companies interested to collaborate with NAMIC, find out more or email namicinfo@namic.sg

References

[1] ‘Additive Manufacturing for Product Development and Rapid Prototyping of Electric Powertrain’ by EVreporter, 26 Nov 2020

[2] ‘Parliament: S’pore needs more than the planned 28,000 electric vehicle charging points by 2030, says Ong Ye Kung’ by The Straits Times, 14 Oct 2020

Bralco Advanced Materials

Address: 81 Ayer Rajah Crescent #03-66, JTC Launchpad @ One North, Singapore 139967

Phone: +65 9896 9552

Contact Person: Mr Amit Nanavati, Founder CEO

Email: amit@bralcoadvancedmaterials.com

LinkedIn: Bralco Advanced Materials

Website: www.bralcoadvancedmaterials.com

Bralco Advanced Materials is listed in NAMIC’s AM Business Directory, find out more: