Intelligent Monitoring System (IMS) for Powder Bed Fusion Process

Key Information

AM Tech

Powder Bed Fusion (PBF) Industry

Aerospace, Automotive Potential Applications

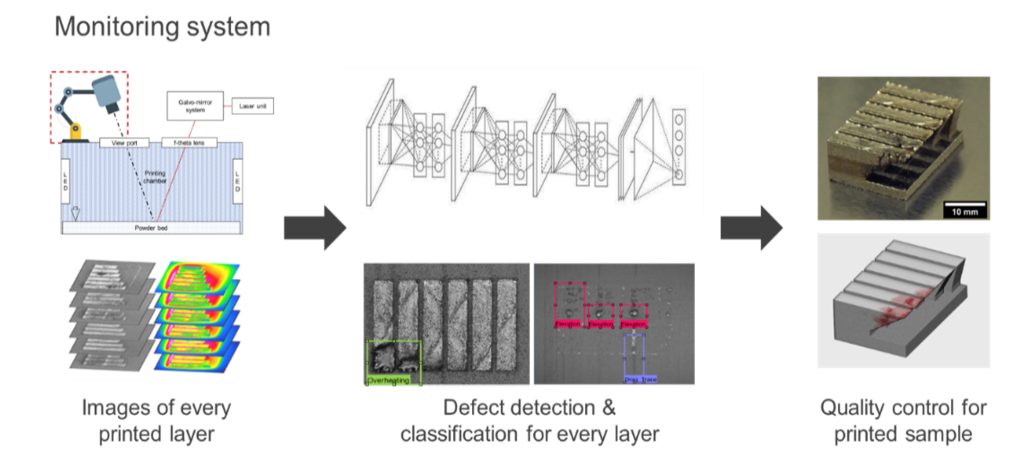

- Ideal for operators of powder bed fusion additive manufacturing systems (e.g., service bureaus, equipment owners)

- Will serve as the basis for standardisation and certification of AM products.

Collaborators

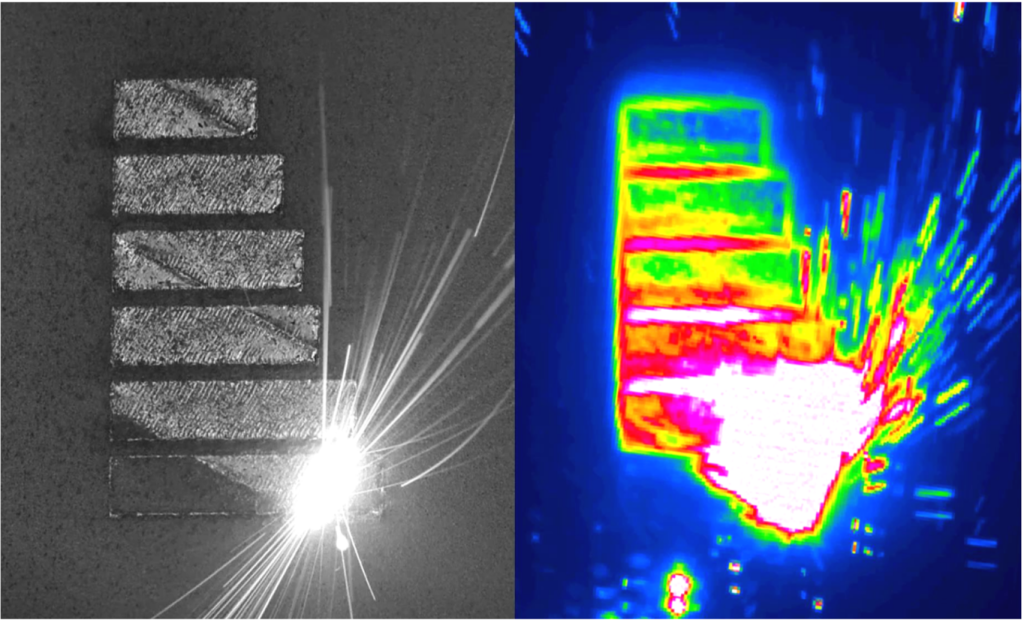

SC3DP (NTU) X ASTM Problem Statement

- Inconsistencies in quality of built parts is preventing the widespread adoption of PBF, especially in industries where product certification is crucial.

- Current non-destructive evaluation (NDE) methods are not optimised for AM processes.

- Determination of optimum process parameters is mainly empirical and varied by different users without a consensus benchmark.

- Current available monitoring systems are mainly developed for a particular process defect and merely used for observation purposes.

Objective

- To provide a multi-control approach for in-situ observation of a range of process defects in PBF process.

- To establish the relationships between defect signatures with a quality-control metric of the fabricated products.

Key Benefits/Outcomes

- Improved print consistency, part quality and reliability.

- Reduced wastage in materials and time invested by providing real-time feedback on the quality of the part being fabricated.

- Increase efficiency in manufacturing process, and greater acceptance of PBF parts in industries such as aerospace, automotive and medical

- Generated 2 publications, 1 technical disclosure and 1 patent