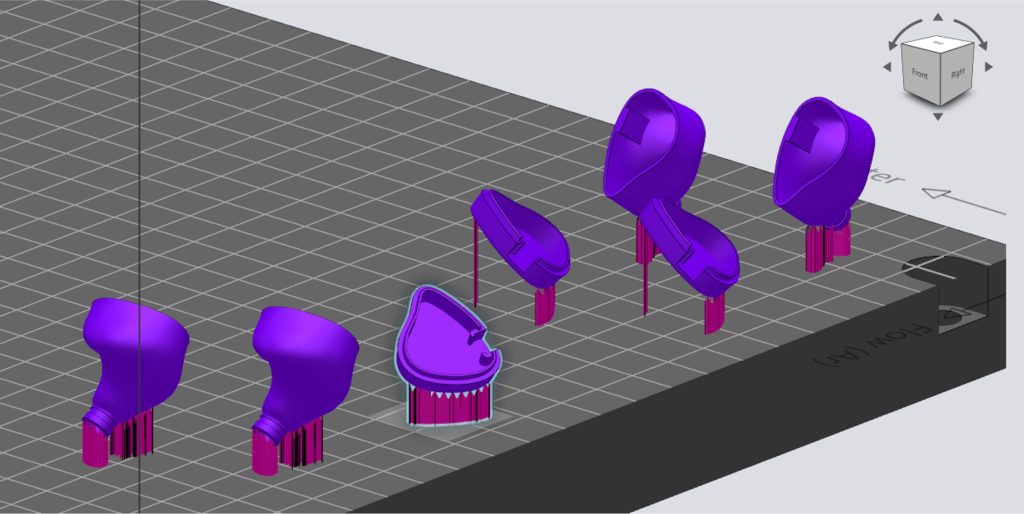

Direct Metal 3D Printed In-Ear Monitors (IEMs) Casing to Improve Fit and Audio Output Transmission Quality

Key Information

Customisation of implants, hearing aids, medical device development, improvement of audio industry application

Problem Statement

Expensive machining costs for low production and/or customised IEM coupled with difficulty in sourcing suppliers to product parts makes it difficult to machine complex casing. Current aluminium parts of IEM are also susceptible to scratches which may also compromise the fit and audio transmission quality for the user.

Objective

The purpose of this project is to employ direct metal 3D printing technology to develop a customised in-ear monitor (IEM) casing that enhances both fit and audio transmission quality. By utilising state-of-the-art printing methods and selecting appropriate materials, the project aims to create an IEM casing that provides exceptional sound transmission and a secure, comfortable fit for the user. The outcome of the project will be evaluated through thorough testing of the fit and audio transmission quality of the final product, with the ultimate goal of delivering an optimal listening experience for the end-user.

Key Benefits/Outcomes

- Producing the custom design of the IEM casing using direct metal 3D printing will provide a better fit for the user, ensuring that the IEM stays securely in place and providing a comfortable listening experience.

- The project aims to improve the audio output transmission quality, which will result in clearer and higher sound accuracy for the user.

- Customising the design of the IEM casing allows for individualised solutions, providing a unique and personalised experience for the user.

- The improved fit and enhanced audio transmission quality of the IEM casing will increase its overall functionality, making it a more attractive product to potential customers.