Design & Manufacture of Decorative Architectural Panels Using Large Scale Robotic Additive Manufacturing

Key Information

SUTD and DB Schenker have enabled Additive Manufacturing for large-scale panels using robotic manufacturing, with the prospect of processing recycled polymers into large-scale components and upcycling waste into panels. Benefits of using Additive Manufacturing:

- Significantly less waste

- Enables true geometric freedom

- Reuse of polymer material

Problem Statement

DB Schenker is a global logistics company. In the quest for a more sustainable logistics process, it is opening a new headquarter in Singapore. One of the main impacts of logistics is packaging waste, such as discarded cardboard boxes, plastic bottles, foam packages, and wood pallets. To help solve this problem, SUTD and DB Schenker are researching ways to convert waste into the same elements that will furnish their new offices. Through this initiative, these wastes are given a second life through 3D Printing and advanced manufacturing methods, producing aesthetic, functional furniture and decorative chandeliers.

Objective

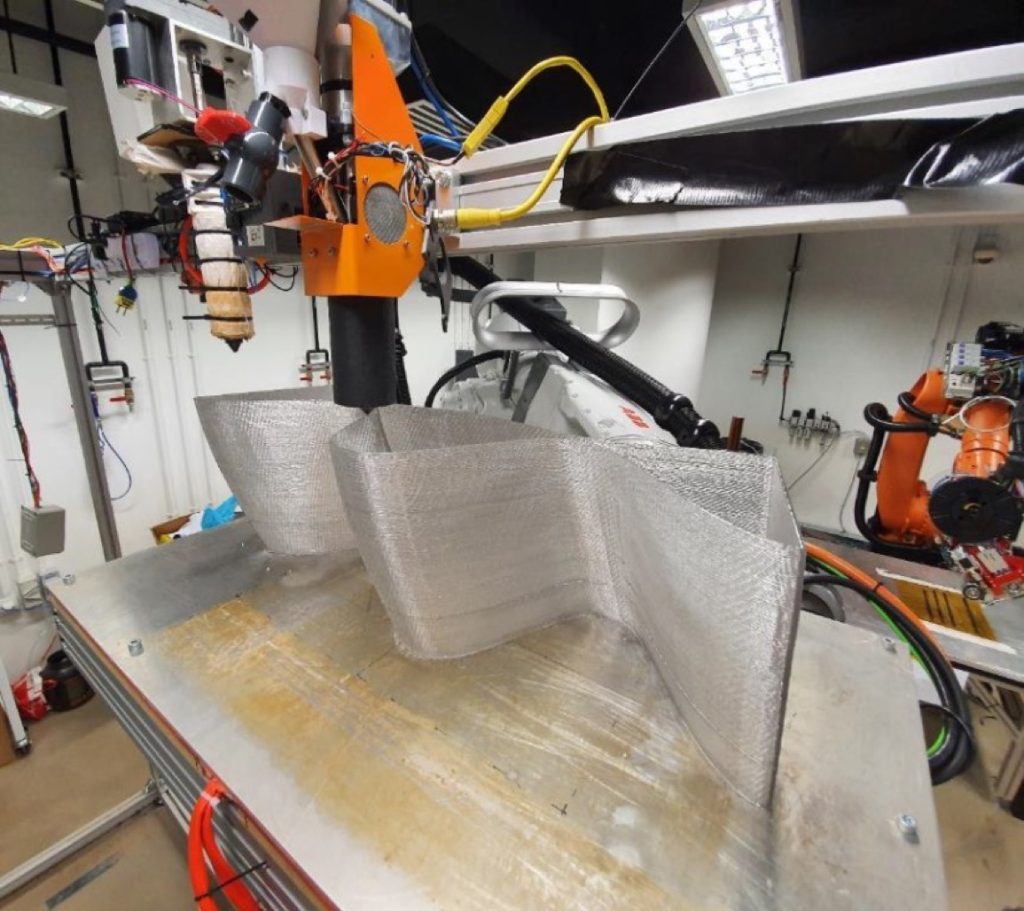

To use recycled PET material extrusion, complemented with the design and manufacturing of several small prototype leading to a large, functional proof-of-concept. The results of the project will be used to draw conclusions about cost, time, and process and therefore accelerate the adoption of AM for manufacture of large format polymer structures in industry.

Key Benefits/Outcomes

- Enabled geometric exploration of tile design, tooplaths and connection systems using large format robotic extrusion AM.

- Fully functional recycled furniture which include:

- three-meter dome dining chandelier made from recycled PET bottles using a custom fabrication process that takes single-use bottles and converts them into filament to 3D print the 450 complex pieces of the chandelier. The texture and porosity are achieved using mathematical surfaces.

- The 3.6m dome is made from recycled bottles using a unique, large-scale robotic printing process.

- The wood pellet tables are made from a geometric interplay of polygons materialized into a stack of reused wood pallets.

- The chair design takes advantage of the softness of the polyethylene packing foam, repurposing the single-use materials into long-life furniture.

- The coffee table reuses corrugated cardboard from packaging

The prototypes are currently installed and used in the DB Schenker Upcycling Hub and have been awarded the SG Mark Award 2022 in Sustainability Category.