3D-printed spacers for reverse osmosis (RO) membrane spiral wound module (SWM)

Key Information

Water treatment, separation technologies

Problem Statement

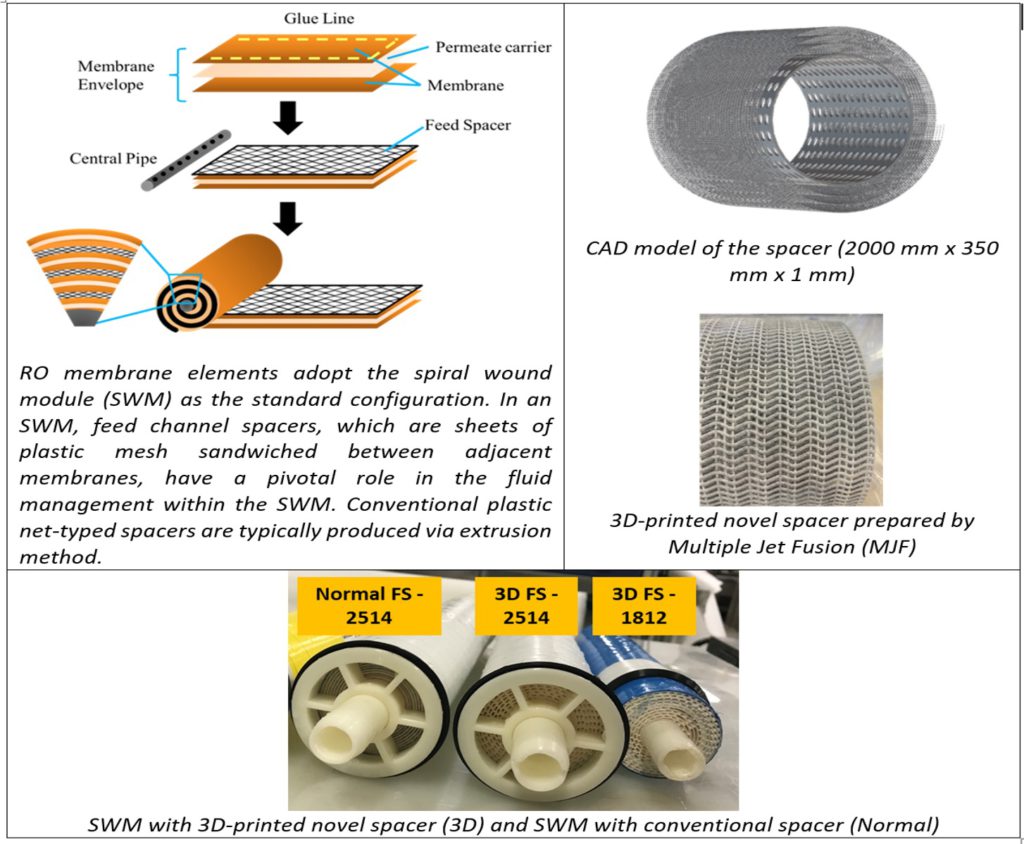

Spacers are critical for reverse osmosis (RO) membrane spiral wound module (SWM) in the desalination process. Ideal spacers have enhanced mass transfer, lower pressure drop, and reduced fouling to reduce the cost and energy demand of the RO process. Conventional method of spacer fabrication hard to realise the complex geometries, but 3D printing can fabricate these spacers.

Objective

Optimization of feed spacer is necessary to reduce the cost and energy demand of the RO process, but the spacer designs are restricted by geometrical constraints. The project aims to develop prototypes of novel spacer for SWM via additive manufacturing (AM):

(i) Fabrication of feed channel spacers with higher degree of freedom, with complex geometries that maximise mass transfer, minimise pressure drop and fouling;

(ii) The novel spacers are be inserted into the SWM configuration;

(iii) The performance of SWM with novel spacers will be validated.

Key Benefits/Outcomes

Prototypes of novel spacer has been 3D-printed and inserted into an SWM. The SWM with 3D-printed novel spacer demonstrated overall improvement in performance with 34% lower inorganic fouling and 47% lower biofouling as compared to SWM with conventional spacer. A Technology Disclosure on “Method For 3D Printing of Large Scale Sheet-Like Models” has been filed (SG Provisional 10202008238T).