A team of engineers from the Singapore University of Technology and Design (SUTD) and the Industrial Technology Center of Wakayama Prefecture in Japan have introduced a new method for ensuring even shrinkage in 3D-printed structures under heat treatment.

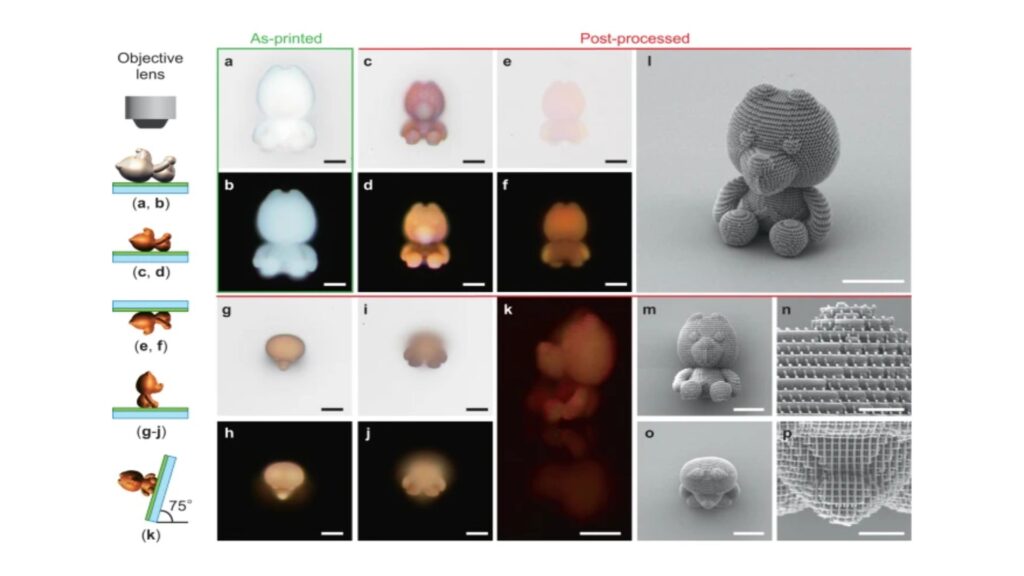

The surprisingly simple solution is to add a layer of polyvinyl alcohol (PVA) to the initial printing substrate, making it easier for the researchers to wash off the 3D-printed parts and transfer them onto a separate substrate. The researchers noted that this technique also introduces the possibility of transferring microscopic 3D-printed parts for integration with other devices or onto substrates unsuitable for two-photon polymerisation lithography.

Read more about their research “Pick and place process for uniform shrinking of 3D printed micro- and nano-architected materials” here.