Researchers at Stanford University have introduced a new process for microscale 3D printing that can print up to 1 million highly detailed and customisable particles a day.

This work builds on a printing technique known as continuous liquid interface production (CLIP), which uses UV light, projected in slices, to cure resin rapidly into the desired shape. The technique relies on an oxygen-permeable window above the UV light projector.

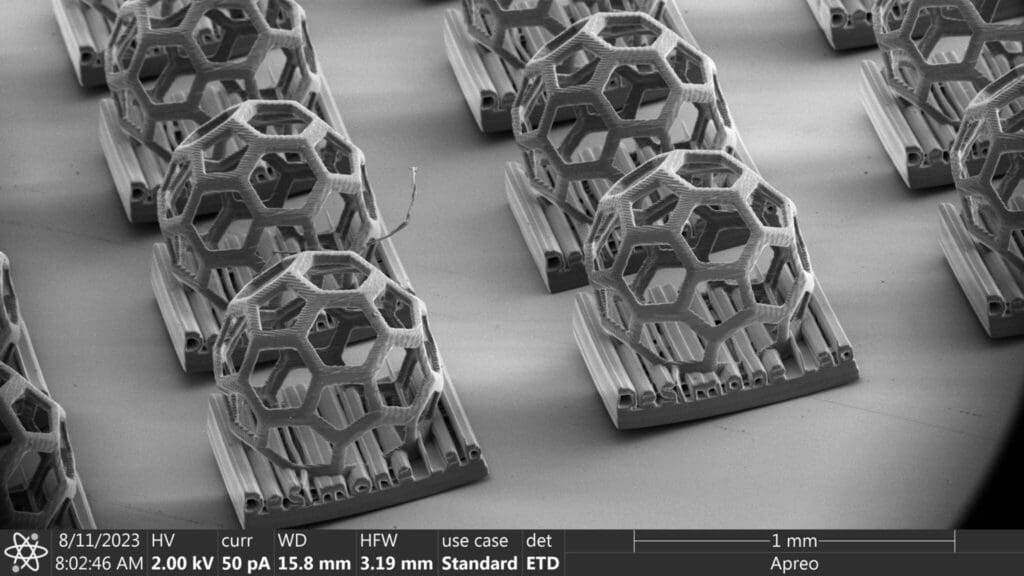

The process that these researchers invented starts with a film that is carefully tensioned and then sent to the CLIP printer. At the printer, hundreds of shapes are printed at once onto the film and then the assembly line moves along to wash, cure, and remove the shapes. At the end, the empty film is rolled back up, giving the whole process the name roll-to-roll CLIP, or r2rCLIP.

The researchers hope that the r2rCLIP process sees wide adoption by other researchers and industry.

Read more about it here.