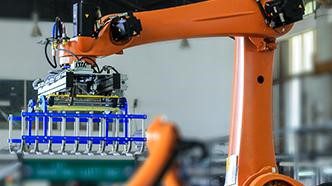

It’s been less than 25 years since the first grippers went into production for industrial applications. The push for more manual dexterity is becoming urgent due to rising demand.

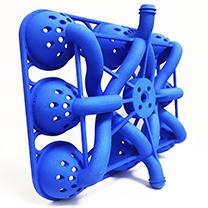

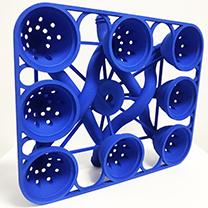

Installed at the ends of regular robot arms, these grippers use sucking air currents to lift and move large, heavy items that can be breakable or flimsy. Multiple air supplies are usually required with integrated vacuum generation boosting volume flow for secure gripping. The design incorporates integrated functions such as air channels for multiple use and combines assembly features for clips and springs.

There is no assembly time or tooling required due to the additive manufacturing process. Standard turn around for this part was 4 days however we offer a 24 hour turnaround if required. Customisation is almost limitless. Serial numbers can be printed with post processing options such as inserts, colouring, vibro polishing etc.

Source: 3T Additive Manufacturing

Click here for the original article.