Perhaps not known to many, but Additive Manufacturing – more commonly known as 3D printing – plays a significant role on the silver screen, be it onscreen or offscreen. Invented in the 1980s, 3D printing has been around for decades with a strong growing pervasiveness in recent years, and their presence is consequently reflected in films as well.

|

One of the earliest onscreen representation of 3D printing would be in Darkman (1990), a vigilante superhero who uses 3D bioprinting to produce face masks, enabling him to switch identities while fending off villains.

|

3D bioprinting is a popular catalyst for major plot points in many action films, and we see this again in Mission Impossible III (2006) where Tom Cruise disguises himself with a 3D printed face mask of Phillip Seymour Hoffman.

Cool? Definitely. Realistic? Perhaps not back then, but highly possible now with the advancement of 3D printing technology. After all, Japan is able to 3D print hyper-realistic face masks.

In 2017, we even see movies take bioprinting one step further in Alien: Covenant. Progressing ahead of their predecessors, the film’s commercial featured a 3D printed lattice of an android skeleton, followed by the bioprinting of human skin which allowed the android to take on a fully human appearance.

|  |

Besides making an appearance on the big screen, 3D printers play a more significant role behind the scenes. Ever wondered how the fine details of props and lifelike character costumes are painstakingly made? 3D printing technology has made this process easier, combined with traditional methods that involve hand sculpting, mould-making and silicon casting.

With 3D printing, special effects studios and costumes designers are able to engage in rapid prototyping, allowing greater flexibility in trialling character designs while reducing cost and material waste. In addition, 3D printing allows for reproducibility, where numerous identical copies of the costumes and props can be produced. This is particularly useful in the event that they are needed in large numbers or are damaged as producing these by conventional methods would otherwise require an extensive amount of manual labour.

The rapid advancement of 3D printing technology is demonstrable in the Iron Man 2, the Marvel hero movie franchise, where Tony Stark’s gauntlet was actually 3D printed using a Stratasys Objet Eden 3D printer.

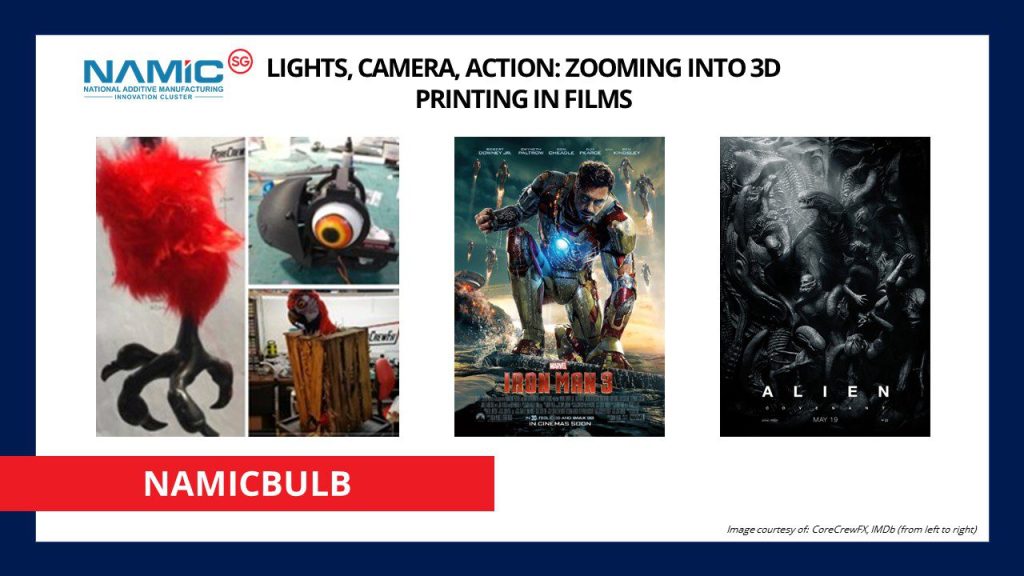

Fast forward three years later in Iron Man 3, the entire costume was 3D printed and tailored proportionately for Robert Downey Jr. by scanning the actor into a 3D model. The special effects studio, Legacy Effects, was able to print 26 life-sized Iron Man suits in the time that it would have taken to produce one clay model. What is even more amazing is that even hobbyist fans were able to replicate and produce a life-sized costume by themselves using 3D printing.

In Singapore, NAMIC has also supported a local film initiative in collaboration with Core Crew Fx, a company based in Singapore specialising in special effects, props and costumes for film and theatre. The company was keen to explore the use of 3D printing in the film industry, which is notably the ability to create life-like parts with greater ease, lower cost and time spent. By working together with the Singapore University of Technology and Design (SUTD), the company successfully created an animatronics parrot with several key achievements:

- A working 3D printed eye and beak mechanism was created.

- A multi-coloured eyeball with gloss surface finish was achieved with the Stratasys J750.

- Both rigid and flexible foot/leg component was printed in one pass with the Fortus 450MC.

The use of 3D printing in the film industry highlights how 3D printing is not an isolated domain, and in reality, art and science are very much deeply interweaved as well.

We can certainly see how 3D printing is becoming more prevalent with time, and it is not just limited to the manufacturing and supply chain industries. By working hand in hand with traditional methods, 3D printing is able to increase productivity and just like how we have seen the printing of visages evolve from an idea to reality, 3D printing and technological advancement have a way of making the impossible possible. What kinds of advancements and possibilities do you foresee 3D printing will bring? How will 3D printing industry look a decade later? Drop us an email at [email protected] and share your thoughts with us.