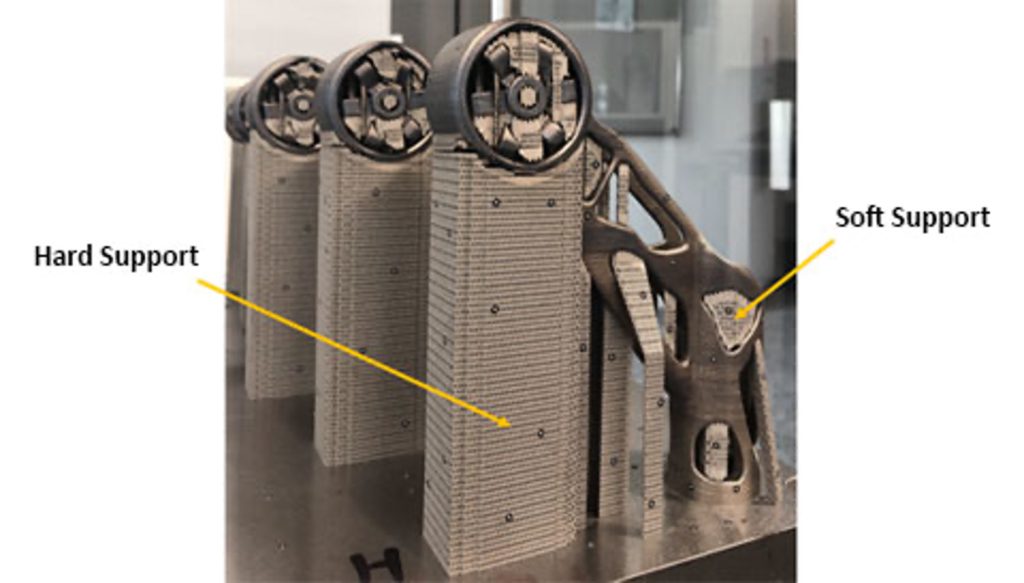

This project aims to develop a soft support system that can be removed by means of sandblasting, instead of using tools such as a chisel or a hammer in areas with little or no access. At locations where the part features large cross-sectional areas such as the one shown in the picture, the hard support system will be applied. In easy access areas, hard or soft supports may be applied, depending on the part feature. In essence, this hybrid system of hard and soft supports can be applied to manufacture a part successfully, without any design constraints. The development of this solution reflects the true advantage of the metal powder bed fusion technology, ie., design freedom.

Temasek Polytechnic

The DFAMC aims to foster, develop and promote the adoption of additive manufacturing technology, also known as 3D printing technology, through design innovation, application projects and capabilities development, relevant to industry’s needs. It also participates in teaching and learning activities in providing the necessary expertise and platforms.

Bringing together a team with complementary suite of expertise, skillsets and facilities to support innovations in the following industries.

Providing a wide range of facilities and equipment to accelerate the adoption of Additive Manufacturing across multiple industries.

AM Technology : DMLS

Choice of Materials : Ti6Al4V Grade 23

Build Size: 250x250x325 mm

Laser Focus Diameter: 100 µm

Minimum Layer Thickness: 20 µm

AM Technology : DMLS

Choice of Materials : AlSi10Mg, MS1, SS316L

Build Size: 100 x 100 x 100 mm

Laser Focus Diameter: 55 µm

Minimum Layer Thickness: 20 µm”

AM Technology : Binderjet (modified)

Choice of Materials : SS316L

Build Size: 100 x 100 x 100 mm

Minimum Layer Thickness: 20 µm

AM Technology : Material Jetting

Choice of Materials : Thermoset Resin

Build Size: 255 x 252 x 200 mm

Minimum Layer Thickness: 16 µm

AM Technology : Stereolithography

Choice of Materials : Thermoset Resin

Build Size: 145 x 145 x 175 mm

Laser Focus Diameter: 140 µm

Minimum Layer Thickness: 100 µm

AM Technology : Fused Deposition Modelling

Choice of Materials : Thermoplastics

Build Size: 200 x 200 x 175 mm

Minimum Layer Thickness: 100 µm

AM Technology : Fused Deposition Modelling(Dual Extruder)

Choice of Materials : Thermoplastics

Build Size: 295 x 240 x 240 mm

Minimum Layer Thickness: 100 µm

AM Technology : Fused Deposition Modelling(colour)

Choice of Materials : Thermoplastics

Build Size: 200 x 200 x 200 mm

Minimum Layer Thickness: 100 µm

To learn more about the equipment and facilities at DFAMC facility, please visit here.

Explore the breakthrough of additive manufacturing through constant research & development projects.

The objective of this project is to reduce manual operations in dental lab manufacturing. The picture demonstrates the product of cobalt chrome coping and porcelain fused to CoCr dental crowns manufactured using 3D printing technology.