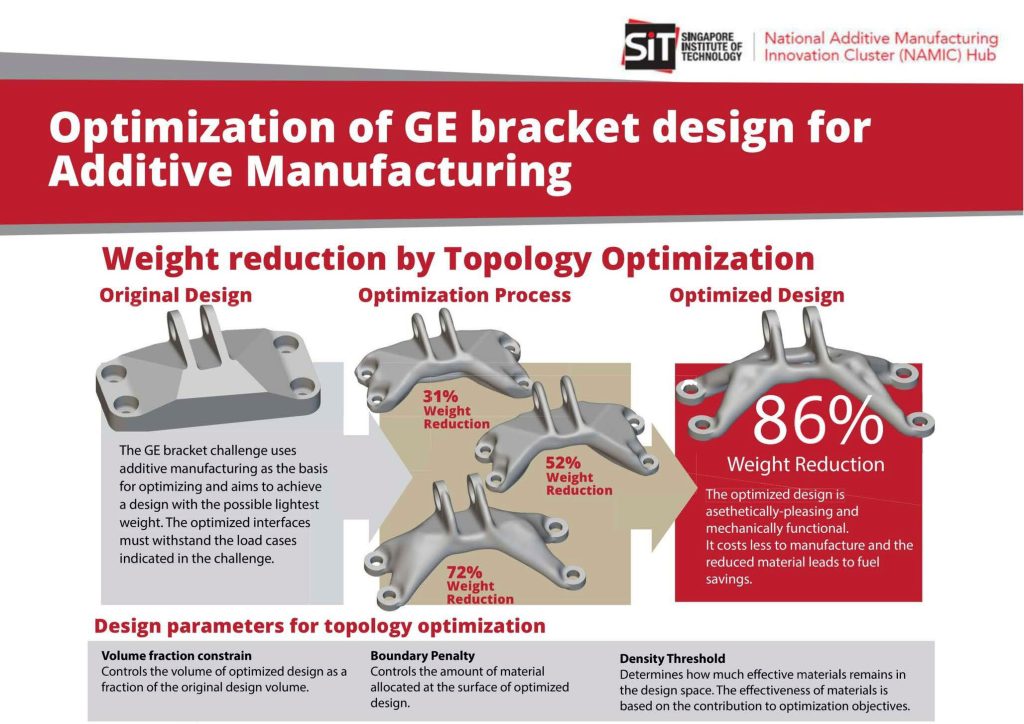

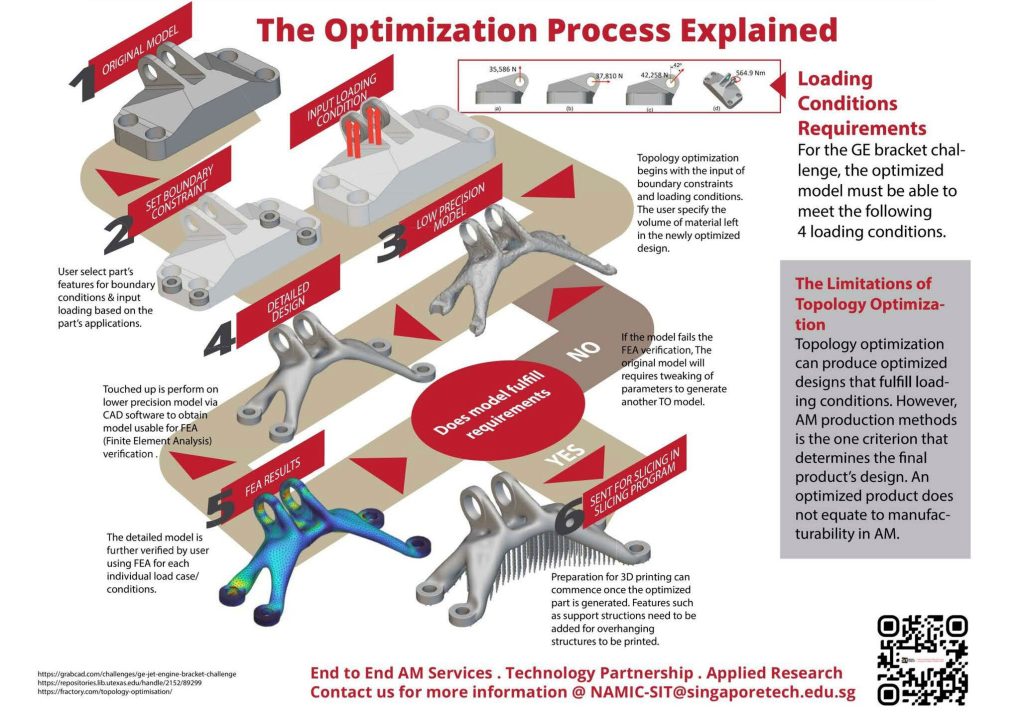

The GE bracket challenge uses additive manufacturing as the basis for optimization and aims to achieve a design with the possible lightest weight. The optimized interfaces must withstand the load cases indicated in the application. With topology optimization augmented optimization, 88% of weight reduction was achieved in the simulation environment.

Singapore Institute of Technology

NAMIC hub@SIT aims to be the catalyst of transformation to boost participating companies’ competitive strengths through additive manufacturing technology.

Bringing together a team with complementary suite of expertise, skillsets and facilities to support innovations in the following industries.

Providing a wide range of facilities and equipment to accelerate the adoption of Additive Manufacturing across multiple industries.

AM Technology: Powder Bed Fusion

Build Space: 190 x 332 x 248 mm

Thickness Height: 0.08mm

Materials: Polyamide Powder

AM Technology : FDM

Build Space : 355 x 254x 355 mm

Thickness Height : 0.127 to 0.330 mm

Min Feature Size : 2.5 mm

Materials : ABS-ESD7, ABS-M30, ABS-CF10, PLA, ASA, TPU-92A. PC-ABS

AM Technology : FDM

Build Space : 700 x 700 x 820 mm

Thickness Height : 0.2 to 0.9 mm

Min Feature Size : 0.8 to 2.4 mm

Materials : PLA, PVA, Woodfill, PET, Bronzefill, Flexible PLA

Industrial Grade Carbon Fiber Printer – MarkForged X7

AM Technology : Continues Fiber Reinforce

Build Space : 330 x 270 x 200 mm

Thickness Height : 0.050 to 0.250 mm

Materials : TPU 95, PLA, Nylon, Carbon Fiber, Fiberglass, Kevlar, Onyx

Manufacture Grade Printer – MarkForged Onyx One

AM Technology : FDM

Build Space : 320 x 132 x 164 mm

Thickness Height : 0.1 to 0.2 mm

Min Feature Size : 0.8 mm

Materials : Onyx (Carbon fiber with nylon)

AM Technology : PolyJet

Build Space : 294 x 192 x 148.6 mm

Thickness Height : 0.016 to 0.036 mm

Min Feature Size : 0.5 mm

Materials : Tough, Rubber-like, Rigid Opaque, Clear, High Temp, Biocompatible, Simulated PP

Plastic Filament Maker – 3devo Composer Series 450

Technology : Plastic Extrusion

Filament Range : 0.5 to 3.0 mm

Filament Materials : PLA, ABS, PS, PC, PETG, TPU, TPE, PPS, PVA, Bio PE, NEW PET, PA (6,12,66), PEEK, PEKK, PAEK, PEI, PSU, PES

Polymer Drying Machine- 3devo Airid

Hopper Size : 5 Liters

Recommended : 1 to 3 kg

Drying Hours : 1kg / 3hrs for PA6

Plastic Shredding Machine – 3devo SHR3D IT

Material Shred : Plastic/Polymer

Granulator Knife : 3 knives/ 900rpm

Shredder Knife : 6 blades// 9rpm

Filter Hole Size : 3mm

Travel X Y Z : 500 x 450 x 400 mm

Spindle Speed : 12k to 20k rpm

Torque : 88 to 120 Nm

Swivel Axis : -65 / +120º

Go! Scan 50

Max Resolution : 0.500 mm

Accuracy : 0.050 mm

Recommended Parts : 0.3 to 3.0 meters

Go! Scan 20

Max Resolution : 0.200 mm

Accuracy : 0.100 mm

Recommended Parts : 0.05 to 0.50 meters

Artec Space Spider

Max Resolution : 0.1 mm

Accuracy : 0.05 mm

Recommended Parts : 0.05 to 0.50 meters

Capable of Full Color Scanning

Max Resolution : 0.02 µm

Accuracy : 1.7 +3L/1000 µm

Recommended Parts : up to 0.7 meters

AM Technology : Powder Bed Fusion (SLM)

Build Space : 250 x 250 x 250 mm

Thickness Height : 0.05 mm

Laser Precision : ±0.03 mm

Min Feature Size : 0.2 to 0.6 mm

Technology : Precision Machining (Cutting)

Spindle Speed : 6k to 45k rpm

Torque : 0.8 Nm

Cutting Precision : 0.1 μm

Materials : Maraging Steel, Stainless Steel, Aluminum, : Inconel 718, Cobalt Chrome, Titanium-64

To learn more about the equipment and facilities at NAMIC hub@SIT, please visit here.

Explore the breakthrough of additive manufacturing through constant research & development projects.

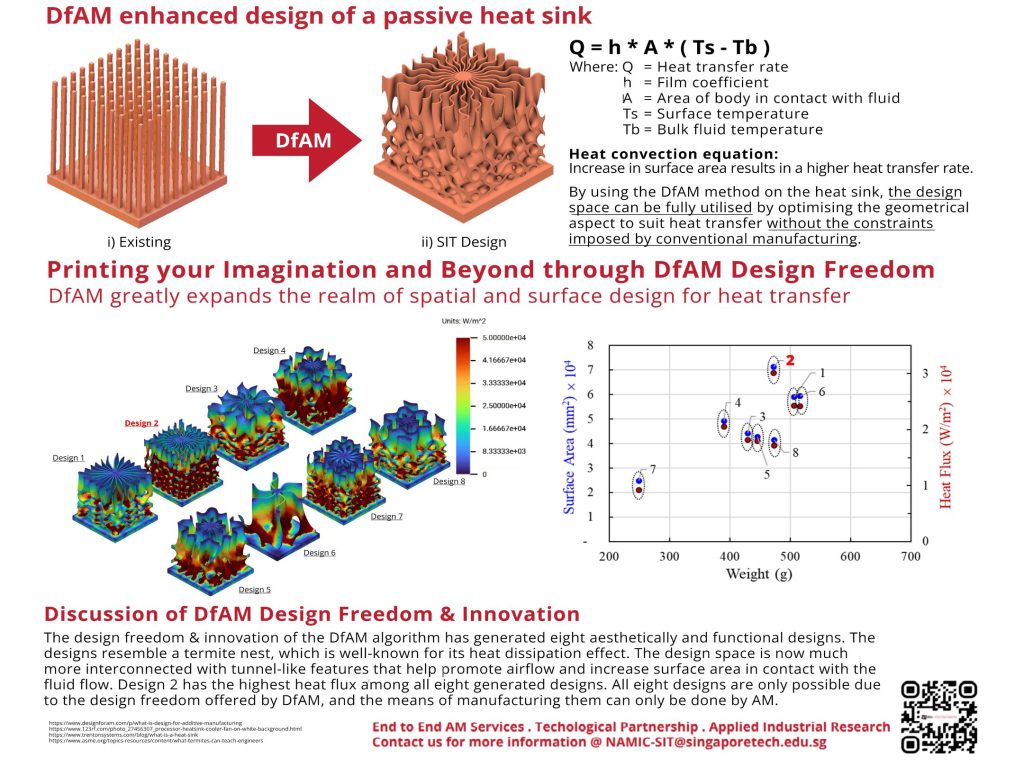

Heat exchangers are crucial in many heat transfer applications, from cooling electronics to recuperating heat in industrial facilities. However, for many high-performance applications like modern computing, we have reached the limit of what is technically possible using traditional manufacturing methods in terms of heat exchanger efficiency or size. The design freedom brought upon by additive manufacturing technology has broken the design barriers and allows one to create more innovative designs and empowers them to optimize heat exchanger performance.