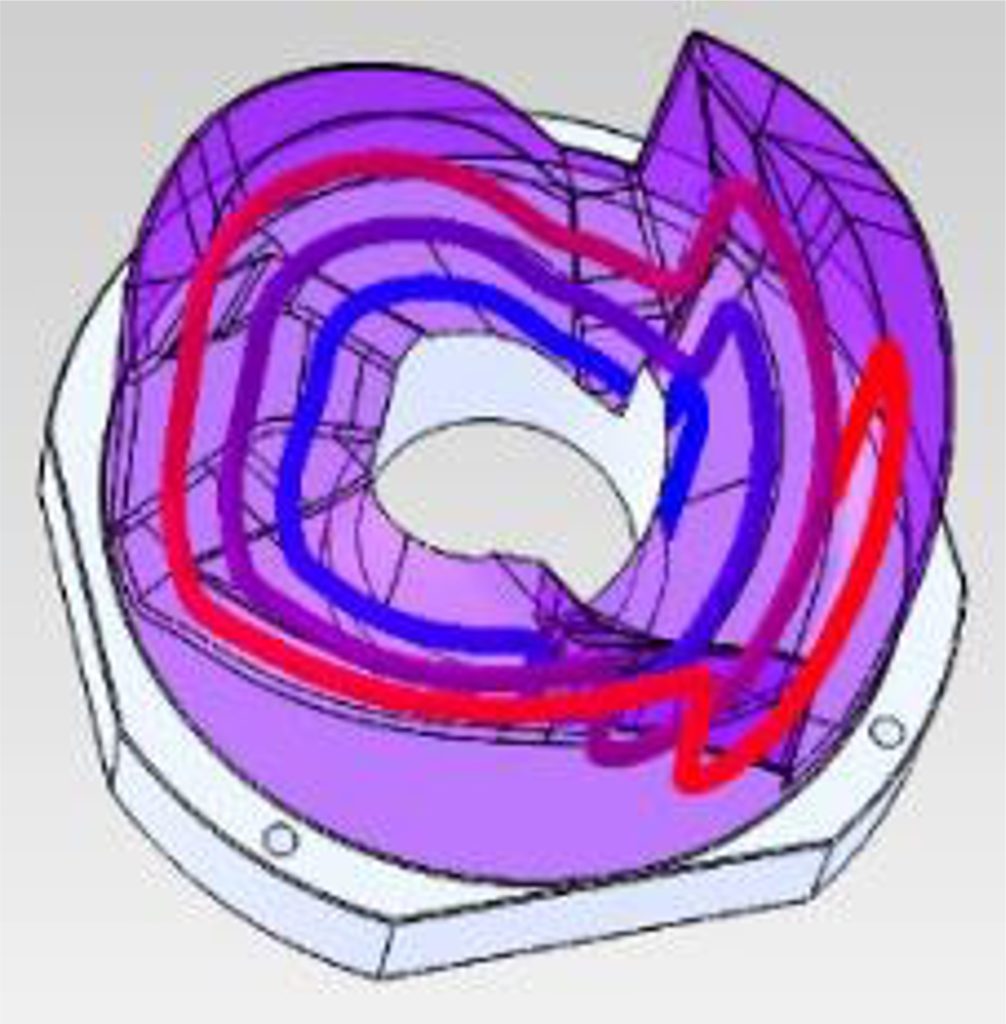

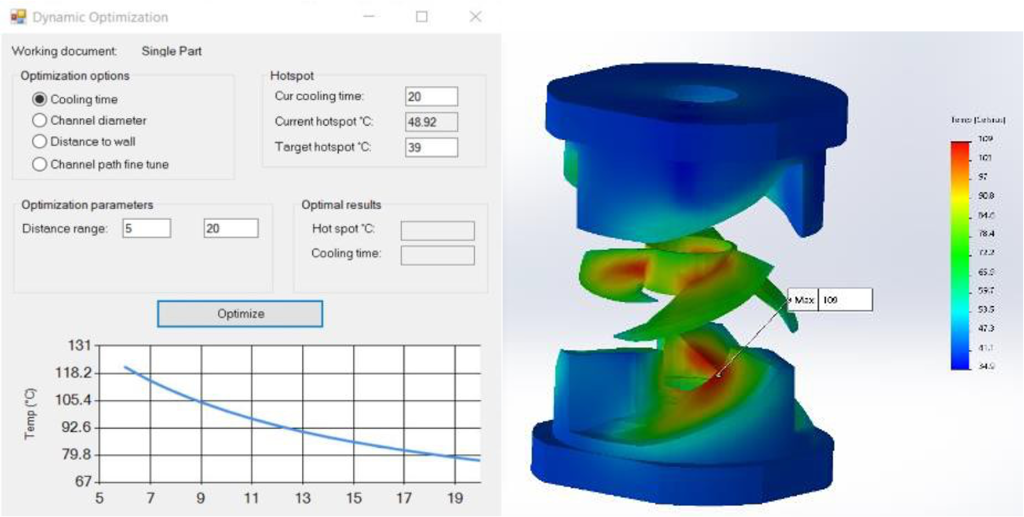

This project is a development of software product and solution for automatic design and optimization of conformal cooling channels, which incorporates dynamic thermal analysis and assessment in a single system. The software could automatically Design and Optimize Conformal Cooling channels. As this software comes with a real-time dynamic thermal analysis, hot spots can be easily identified and corrected. It enhances the manufacturing productivity by improving part quality, reducing design lead time and tooling verification time. The solution also minimizes the dependence on human knowledge capital and solve the manpower intensive process in developing rapid tooling with conformal cooling.

Nanyang Polytechnic

The Additive Manufacturing Innovation Centre (AMIC) located at Nanyang Polytechnic supports industry in meeting the challenges of product design and development, technology adoption, manpower training, applied research and development in additive manufacturing.

They have a team of experienced and competent professional senior development engineers and development technologists in various technological areas are well-prepared and dedicated to take on the challenge and needs of industry.

Bringing together a team of experienced and competent professional Senior Lecturers, Development Engineers and Development Technologists in various technological areas to tackle industry challenges and needs in the following industries.

Providing a wide range of facilities and equipment to accelerate the adoption of Additive Manufacturing across multiple industries.

Process: Scanning of laser beam over the cross section of the model in the metal powder and building up layer by layer.

Material used: Stainless Steel, Maraging Steel (MS1), Aluminium (AlSi10Mg), Titanium (Ti64), Inconel 718

Maximum Build Size: 250mm x 250mm x 325mm

Laser Focus Diameter: 100 µm

Minimum Layer Thickness: 20 µm

Application: Rapid Tooling Insert with Conformal Cooling, Metal components, Hybrid prototypes, Other applications

Process: Scanning of laser beam over the cross section of the model in the metal powder and building up layer by layer.

Material used: Stainless Steel, Maraging Steel (MS1), Aluminium (AlSi10Mg), Titanium (Ti64), Inconel 718

Maximum Build Size: 250mm x 250mm x 325mm

Laser Focus Diameter: 100 µm

Minimum Layer Thickness: 20 µm

Application: Rapid Tooling Insert with Conformal Cooling, Metal components, Hybrid prototypes, Other applications

Process: Scanning of laser beam over the cross section of the model in the metal powder and building up layer by layer.

Material used: Stainless Steel, Maraging Steel (MS1), Aluminium (AlSi10Mg), Titanium (Ti64)

Maximum Build Size: 250mm x 250mm x 280mm

Minimum Layer Thickness: 20 µm

Laser Focus Diameter: 90 µm

Application: Rapid Tooling Insert with Conformal Cooling, Metal components, Hybrid prototypes, Other applications

Process: Powder-based technology utilising IR energy to fuse powder with light-absorbing ink and detailing agent.

Material Used: Polyamide (PA 12)

Maximum Build Size: 380mm x 284mm x 380 mm

Min Layer thickness: 0.08 mm

Application: Conceptual model, Fit, form and functional applications, Functional prototypes, Other applications

Process: Scanning of UV laser beam over the cross section of the model in liquid resin and building up layer by layer.

Material Used: Accura 60(PC Similar)

Maximum Build size : 650mm x 750mm x 550mm

Min Layer Thickness: 30 µm

Application: Concept modeling, Form fit, assembly tests, Master pattern for vacuum casting, Models for stress optical checking, Other applications

Process: Inkjet print heads are used to deposit materials on demand onto a build platform. The material solidifies which allows to build layers on top of each other.

Material Used: Clear, rubberlike photopolymers, and tough high-performance thermoplastics. Able to combine many colors and material properties into one model.

Maximum Build size: 490mm x 390mm x 200mm

Min Layer Thickness: 16 µm

Application : Concept modeling, Form fit, assembly tests, Functional Prototypes, Transparent and rubber like model, Other applications

Process: The extrusion head heats the filament and ‘draw’ section of the part on the build platform. Model is built upwards in layer.

Material Used: ABS, PC, PC-ABS, Ultem

Maximum Build Size: 900mm x 600mm x 900mm

Minimum Layer Thickness: 125 µm

Application: Conceptual model, Fit, form and functional applications, Investment casting, Other applications

“Process: The extrusion head heats the filament and ‘draw’ section of the part on the build platform. Model is built upwards in layer.

Material Used: ABS, PC, PC-ABS, Ultem

Maximum Build Size: 400mm x 350mm x 400mm

Minimum Layer Thickness: 127 µm

Application: Conceptual model, Fit, form and functional applications, Functional prototypes, Other applications”

Process: The extrusion head heats the filament and ‘draw’ section of the part on the build platform. Model is built upwards in layer.

Material Used: ABS

Maximum Build Size: 254mm X 254mm X 254mm

Min Layer Thickness: 125µm

Application: Conceptual model, Fit, form and functional applications, Functional prototypes, Other applications

Copper 3D-printing with powder bed fusion technology enables precise, high-density copper printing with enhanced thermal and electrical properties.

Process:

The DLyte 100PRO is a cutting-edge compact surface finishing machine designed for industrial applications. It utilizes dry electropolishing technology to precisely smooth, polish, and deburr metal parts, offering high-quality results faster and more efficiently than traditional methods.

Material used:

Stainless Steel, Cobalt-Chrome, Titanium, Nickel-based alloys & Tool steel.

Maximum Part Size:

The maximum part size depends on the machine’s chamber size, which is 180 mm (Diameter) x 80 mm (Height). However, it is mainly used for polishing parts smaller than 100 mm (Diameter) x 50 mm (Height).

Applications:

- Automotive

- Semiconductor

- Medical & Dental components

- Aerospace components

- Precision Components

Precisely smoothening, polishing, and deburring metal parts, Dry Electropolishing offers high-quality results faster and more efficiently than traditional methods. It provides superior surface finishes, including mirror-like finishes and defect-free surfaces, that outperform traditional polishing.

Process

The Markforged FX10 uses a Continuous Filament Fabrication (CFF) process, which combines the deposition of layers of thermoplastic filament with reinforcement filaments such as carbon fiber. The printer’s dual extrusion system allows it to print both the base material (such as Onyx) and the reinforcing material simultaneously.

Material used:

OnyxTM, Onyx FRTM Onyx ESDTM

Maximum Build Size:

375 mm x 300 mm x 300 mm

Application:

- Tooling & Manufacturing Fixtures

- End-Use Parts

- Functional Prototypes

- Aerospace Components

- Replacement Parts

To learn more about the equipment and facilities at AMIC, please visit here.

Explore the breakthrough of additive manufacturing through constant research & development projects.

Jointly conducted with the American Bureau of Shipping (ABS):

Jointly Conducted with Materialise: