-

Welcome to the NAMIC Global AM Summit!

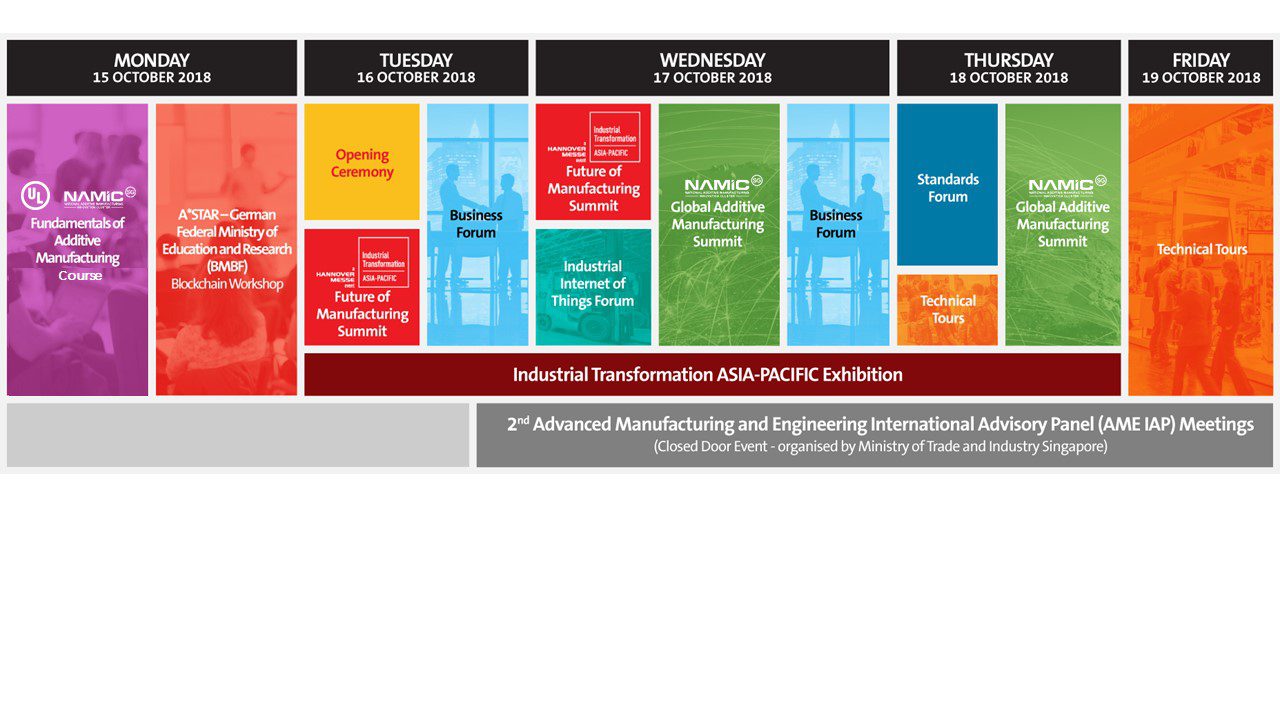

The 2-day NAMIC Global Additive Manufacturing Summit, co-located as part of Industrial Transformation ASIA-PACIFIC, is presented by the National Additive Manufacturing Innovation Cluster ( NAMIC), hosted by NTUitive, as part of its NAMIC AM Summit series to raise awareness and thought leadership.

The Plenary session on day 1 highlights key AM developments and opportunities in Aerospace, Marine, Building and Construction, Healthcare, Design and Emerging applications while the parallel tracks on day 2 dives deeper into AM topics in specific Industrial sectors such as Transportation, Automotive and Biomedical.

Programme Framework

UL-NAMIC Fundamental of Additive Manufacturing Course

Description

In conjunction with the Industrial Transformation ASIA-PACIFIC-a HANNOVER MESSE event, UL and Singapore based National Additive Manufacturing Innovation Cluster (NAMIC) present the inaugural international launch of the UL and Tooling-U SME Additive Manufacturing Fundamentals Review Program and Certification Exam. In response to global industry feedback, this program provides enhanced workforce training and development efforts for manufacturers wanting to increase their capabilities in additive manufacturing.

The UL-NAMIC Fundamental of Additive Manufacturing Course includes the recommended prep course and seated certification exam. The prep course is a discussion-oriented and interactive session in which participants receive comprehensive introductory knowledge of the 3D printing industry. Covering terms and definitions, software and hardware as well as discussing applications and case studies, you will begin to understand the benefits of 3D printing in a way that is relevant to your business needs. The certification exam is a three hour proctored, open book and open note exam consisting of 100 multiple choice questions.

Upon passing the exam, students earn their Additive Manufacturing Fundamentals Certification. The certification may be stackable, creating a flexible, modular pathway for mastering the principles and processes of AM.

Agenda

- 9:00am – 01:00pm: Fundamentals of Additive Manufacturing Prep Course

- 01:00pm – 02:00pm: Lunch

- 02:00pm – 05:00pm: Fundamentals of Additive Manufacturing Course Certification Exam

Review Program Learning Objectives

- Identify the various 3D printing technologies & their benefits/limitations

- Define the basic 3D printing process

- Understand the hardware & software for 3D digital file management

- Identify common materials for each 3D printing technology

- Describe integration of 3D printing with secondary manufacturing processes (e.g. casting & molding)

- Identify basic safety & quality considerations specific to 3D printing

Additional Study Resources

- CLICK HERE for the AM Body of Knowledge. Exam topics are pulled directly from the Body of Knowledge.

- CLICK HERE for a recommended reading list. The main recommended resource is the “Additive Manufacturing Technologies, 3D Printing, Rapid Prototyping, Direct Digital Manufacturing, Second Edition.” All resources on this list are optional.

Logistics

- Date: 15 Oct 2018 | Location: NTU Innovation center, 17 Nanyang Drive, #04-01, Singapore 638075

Target Audience

UL-NAMIC Fundamental of Additive Manufacturing Course is for any business professional, engineer, or designer with a desire to learn about 3D printing and enter the Additive Manufacturing industry.

Certification Exam

To pass the exam, students must receive a score of 70% or higher. After the exam is scored, students will receive official results by mail, which includes an Examination Analysis report that provides a breakdown of your results by knowledge area. Additional information on the seated exam will be provided in advance of the program.

Course Synopsis & FAQ

- CLICK HERE to find out more on the course synopsis and Frequently Asked Questions.

Audience – Who to Attend

What People Said

eNewsletter

eNews #1 eNews #2 eNews #3 eNews #4 eNews #5 eNews #6 eNews #7

Click to download Click to download Click to download Click to download Click to download Click to download Click to download