Raplas is built on partnerships, whether it be with our suppliers of materials and components or with our customer base, working collaboratively to ensure that our solutions exceed expectations. Whether you need impressively large, high-quality prototypes, to develop and launch new products faster, and bring new innovation to market or you want to experience production cost savings for functional parts, Raplas has a product and material for you. More information www.raplas.com

Raplas Technologies Limited

The Company

Products & Services

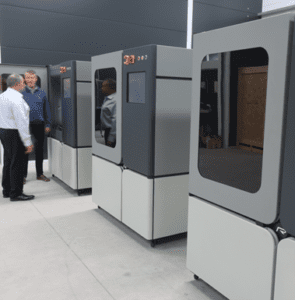

Raplas offers a range of production SLA 3D printers.

PR450 – 450x450x400mm

PR700 – 700x700x500mm

PR800/7 800x700x500mm

Each features a fully open-source capability in both software and materials, has variable depth, interchangeable vats and a lifetime licence for Materialise.

Our powerful 2W, dynamic laser can be controlled at the vector level meaning prints are fast, functional and flawless.

-With an impressive 450x450mm build platform the PR450 is our entry level machine but still offers print capability of >10X a desktop printer.

-The PR700 features an enormous 700 x 700mm bed (>25x the size of a desktop printers) and can print to depths of 500mm. Our flagship printer is a true workhorse for high quality part production.

-At 800x700mm the PR800/7 is capable of printing at a production scale, whilst maintaining accuracy across the whole build

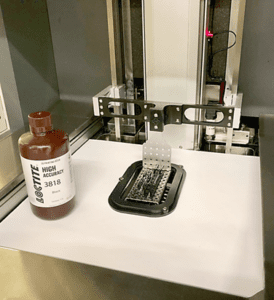

Material Development Kit

Our machines can be fitted with an optional MDK to allow users to test or develop small batches of resin for printability and functional properties without the need to invest in a larger amount

Certified Materials capability

General Purpose

High Temperature

Flame Retardant

Tough

Rigid

Investment Casting

ESD

Ceramic

Bio-Compatible