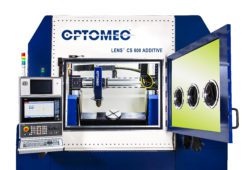

The Optomec company and its two main product technologies were born from the efforts and investments of the United States research labs and technology programs. Founded in 1997, it has been devoted to transferring leading edge additive manufacturing technology from the laboratory to the production floor. The company currently focuses on two groups of solutions: the LENS® (Laser Engineered Net Shaping) Directed Energy Deposition process for metal additive manufacturing and the Aerosol Jet® process for 3D printed electronics. Optomec does not simply supply manufacturing hardware; rather, it provides a synthetic solution comprising machinery, training, materials expertise and process recipes. Hundreds of Optomec systems have been installed in leading manufacturing sites worldwide.

With Optomec, the promise of high-volume additive manufacturing is a reality today, transforming how companies design, build and maintain critical parts and products and enabling new manufacturing possibilities.

Optomec additive manufacturing technology provides compelling advantages over traditional manufacturing approaches.

- It enables customers to not only print full 3D parts, but also to add materials onto existing 3D parts that were produced using conventional manufacturing methods, such as CNC machining or injection molding.

- It provides production grade/production scale 3D printing of fully functional end-use devices in specific areas such as printed electronics and metals.

- It support a wide range of functional materials and feature sizes