m4p (metals for printing) is one of the few, if not the only, metal powders company with a 100% focus on AM. Being solely focused on metal AM gives us certain USPs – a wide product range, short lead times (normally 1-2 weeks from PO), chemistry and powder PSDs controlled within a very narrow range (for consistent performance and reliability of AM produced components).

The company offers a wide range of products some of which we have specially designed / optimized for use in AM (L-PBF, E-PBF, DED, Metal Binder Jetting and Cold Spray). In addition to the commodities widely used on the market, such as stainless steel m4p™ 316l, tool steel m4p™ Fe-2709, universal alloy m4p™ AlSi10Mg, or the high-performance material m4p™ Ti64 grade23, some powders could be of particular interest. For example, m4p™ StrengthAl (Al-Mg-Sc alloy reaching 470 MPa in strength, anodizable and a direct-ageing heat treatment), m4p™ Cu-Cop42 (GRCop-42), m4p™ CXplus (stainless and well polishable maraging steel), m4p™ type13-X (equivalent to ASTM CA6NM), m4p™ type10-SDX and m4p™ type62-DX (a super-duplex steel and a duplex steel, respectively) and many more. What is even more interesting is we can support them with starting process parameters and heat treatment for most of the products we offer.

Heat sink printed in m4p™ PureAl

Printed in m4p™ type13-X�ASTM CA6NM or F6NM

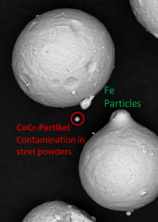

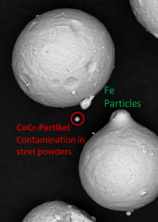

Ppm level particulate powder contamination tested using proprietary method with SEM-EDX

Motorbike frame printed in m4p™ StrengthAl. High-strength, anodizable, direct ageing Al-Alloy