Bright Laser Technologies (BLT) [Stock Code: 688333.SH], is a global leader in providing comprehensive turnkey solutions for metal additive manufacturing and remanufacturing. BLT has developed a mature metal AM ecosystem with a strong focus on industrial metal 3D printers, metal powders, contract manufacturing, innovative software, as well as specialized AM consulting. Drawing on years of metal AM expertise, BLT caters to a wide range of industries. These include aerospace, energy, medical, dentistry, industrial tooling, automotive manufacturing and more. Through continuous innovation, the company strives to meet the evolving needs of its customers. Up to June 30, 2023, BLT has a global presence with approximately 1,400 employees, of which about 30% of them are involved in R&D.

Bright Laser Technologies – BLT

The Company

Products and Services

A) Metal Additive Manufacturing Systems

1) BLT-S800

BLT-S800 features an extra-large build dimension [800mm (W) x 800mm (D) x 600mm (H)] with powerful multiple 500W laser setups (6,8 and 10 lasers), allowing for great rates of large format and high-quality production. The latest BLT S800 can even be configured with 20 fiber lasers should the applications arise. BLT has dedicated extensive efforts to the development of the BLT-S800 Metal Laser-Powder Bed Fusion system, aiming to meet the exacting demands of high-end applications in sectors including aviation, aerospace, automotive, medical, and scientific research.

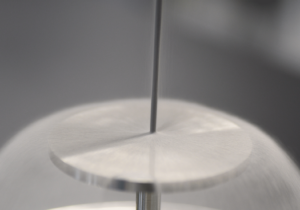

Engine integration component with φ800mm×400mm produced by BLT-S800 in IN718

2) BLT-S400

The Airbus-qualified BLT-S400 provides two build dimension: 400mm×250mm×400mm(W×D×H) and 400mm×300mm×400mm(W×D×H). The high-performance machine is available in several configurations, providing dual optic (2x 500W), triple optic (3x 500W) and quintuple optic (5x500W). Multiple optional laser quantities and two-way intelligent powder feeding dramatically improve production efficiency. BLT-S400 is used for Laser-Powder Bed Fusion of small and medium-sized complex metal components, achieving flawless and precise laser manufacturing.

Fully nested support with 250mm×250mm×400mm produced by BLT-S400 (3-laser) in AlSi10Mg

B) Metals Powders manufacture

- BLT-Ti64

BLT has developed and produced high-quality BLT-Ti64 powders suitable for Laser-Powder Bed Fusion. Advanced Inert Gas Atomization process is adopted to produce BLTM powder. Combined with our optimized powder treatment process, we can provide BLT-Ti64 powder with superior quality in commercial scale.

C) Parts Printing Services

We have the capacity to provide you with high-quality printing services covering parts for various industries. BLT possesses 340 Metal AM machines & systems and more than 60 formable materials, whose components are content with technical specifications, including the standards of aerospace, national, ASTM, AMS, ISO, SAE.

Siemens-designed component (combustion chamber) with 250mm×250mm×400mm produced by BLT-S320 in superalloy

Printing Capabilities

- SLM / LPBF

- Metals