Last held in 2023, the Singapore Additive Manufacturing (AM) Week is a week-long series of AM activities featuring workshops, tours, a conference summit and more within Asia Pacific. Dedicated to the AM ecosystem, the week will bring together international AM experts and industry leaders to connect and exchange valuable insights, applying 3D printing to change the way we design, make and recycle.

-

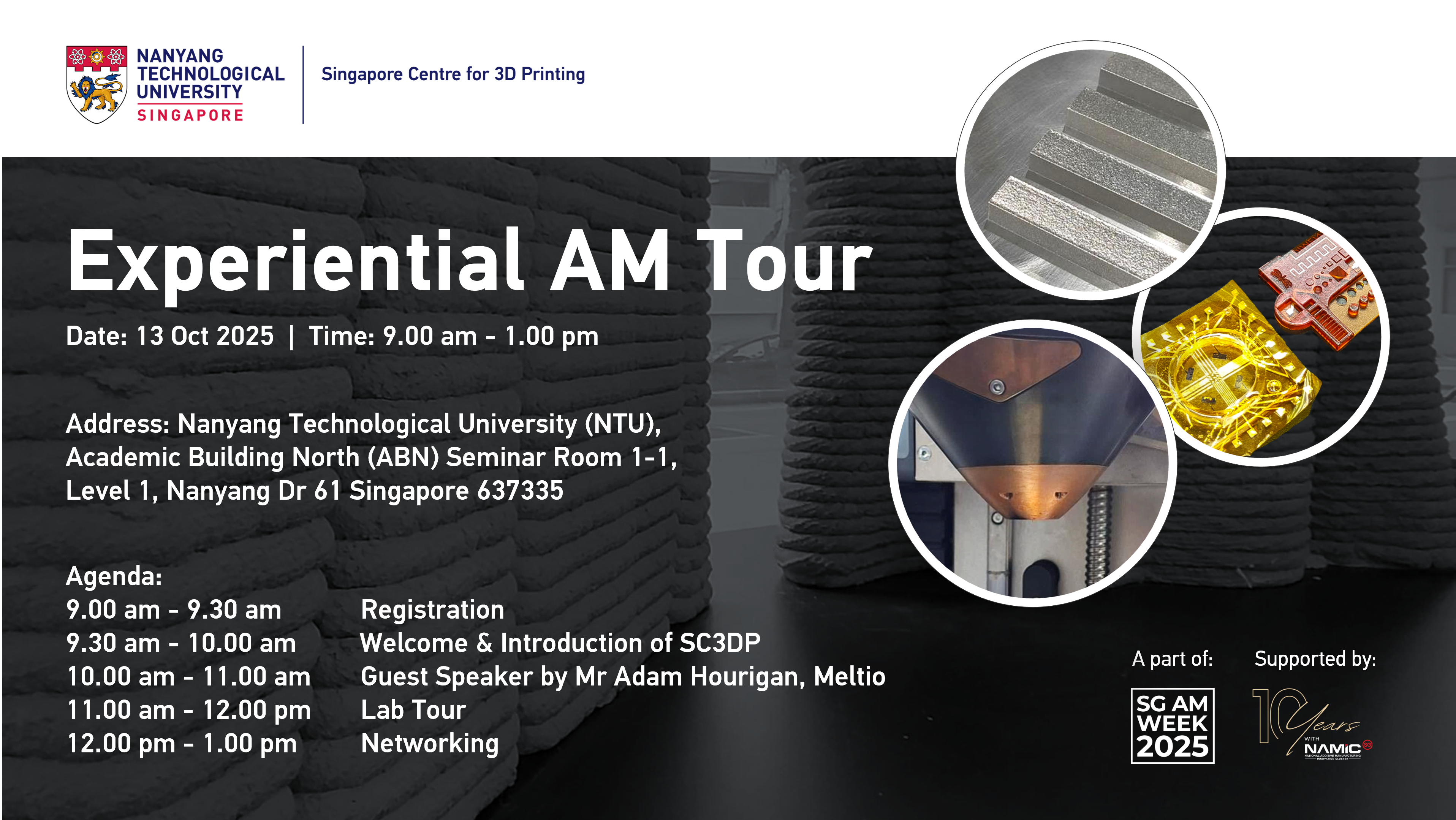

09:30 am — 01:00 pmExperiential AM Tour @ NTU SC3DPNanyang Technological University, Academic Building North (ABN) Seminar Room 1-1, Level 1, Nanyang Dr 61, Singapore 637335

09:30 am — 01:00 pmExperiential AM Tour @ NTU SC3DPNanyang Technological University, Academic Building North (ABN) Seminar Room 1-1, Level 1, Nanyang Dr 61, Singapore 637335At the Singapore Centre for 3D Printing (SC3DP), advanced technologies are transforming key industries such as aerospace, electronics, healthcare, maritime, construction, defence, and energy. During the tour, participants can get to see 3d printing innovations that harness a wide range of materials, including metals, polymers, glass, ceramics, electronics, concrete, composites, and biological substances.

Our guest speaker Mr Adam Hourigan, APAC & UK Sales Manager, Meltio, will also sharing an insightful how Meltio’s wire-laser metal 3D printing technology is creating an transformative impact on real-world industries, and potential applications.

Recommended for general public interested to know more about AM or AM research engineers.9:00 am — 9:30 amRegistration9:30 am — 10:00 amWelcomeIntroduction of SC3DP10:00 am — 11:00 amPresentation by Mr Adam Hourigan, Meltio11:00 am — 12:00 pmLab Tour12:00 pm — 1:00 pmNetworking 09:00 am — 12:30 pmHP’s Solutions Across Diverse IndustriesAdditive Innovation Centre (AIC), A*STAR 5 Cleantech Loop, #03-01 Cleantech Two Block B, Singapore 636732

09:00 am — 12:30 pmHP’s Solutions Across Diverse IndustriesAdditive Innovation Centre (AIC), A*STAR 5 Cleantech Loop, #03-01 Cleantech Two Block B, Singapore 636732The workshop featured an introduction to AIC, followed by a presentation on HP Metal Jet technology and its applications. After a short break and lab tour, participants will move to SMARC for a showcase of HP’s MJF technology, highlighting its speed, precision, and manufacturing potential.

Recommended for AM Professionals9:00 am — 9:30 amRegistration9:30 am — 9:45 amIntroduction to Additive Innovation Centre9:45 am — 10:15 amHP Metal Jet Technology Introduction and Application Showcase10:15 am — 10:30 amBreak and Interaction10:30 am — 11:00 amLab Tour11:00 am — 11:30 amEn-Route to HP SMARCBus transport11:30 am — 12:30 pmHP MJF Showcase 02:00 pm — 06:00 pmSustainable Design: Smart Lattice Structures for AMCADVision Systems Pte Ltd, 31, Kaki Bukit Road 3, #05-09 Techlink, Lobby, B, 417818

02:00 pm — 06:00 pmSustainable Design: Smart Lattice Structures for AMCADVision Systems Pte Ltd, 31, Kaki Bukit Road 3, #05-09 Techlink, Lobby, B, 417818Curious about how design choices can make 3D printing more sustainable without compromising performance? This hands-on workshop, Sustainable Design: Smart Lattice Structures for AM, introduces participants to practical tools and methods that support smarter, greener additive manufacturing. Using SOLIDWORKS, you’ll learn how to model parts, optimise designs, and create lightweight lattice structures that maintain strength while reducing material use. The session also covers eco-design considerations and how to prepare your models for 3D printing with sustainability in mind. Whether you’re working in AM research or simply interested in designing more responsibly, this workshop offers a solid starting point—complete with real-world examples and guided exercises. Participants will receive a certificate of attendance issued by Dassault Systèmes.

Course outline:

– CAD modelling & design optimization

– Lattice designer – to design lattice of the model while maintaining the structural strength

– Eco-Design

– Lattice designer – output to 3D printable formatRecommended for AM research engineers 02:30 pm — 04:00 pmPrint, Prove, Profit: AM-Driven Small-Batch Production for Market Fit Workshop3 Fusionopolis Way, Level 22 One-North Gallery, Symbiosis Tower Singapore 138633

02:30 pm — 04:00 pmPrint, Prove, Profit: AM-Driven Small-Batch Production for Market Fit Workshop3 Fusionopolis Way, Level 22 One-North Gallery, Symbiosis Tower Singapore 138633Come join us at Symbiosis Tower, Level 22 for an exciting event all about the 3D printing production for toys! Dive into the world of 3D printing for toys and discover how this technology is revolutionizing the way we play. Get hands-on experience with 3D printers and learn from experts in the field. Whether you’re a toy enthusiast, a tech lover, or just curious about the future of play, this event is perfect for you. Don’t miss out on this unique opportunity to explore the endless possibilities of 3D printing in the world of toys!

Organisers: Eye – 2 – Eye Communications / Formlabs

Speakers: MoxMonsters (end-to-end toy micro-factory, Singapore)

Recommended for Hobbists, Designers, Creative professionals exploring AM, educators and vocational trainers in toys manufacturing technology and AM professionals interested in high-value, low-volume production.2:30 pm — 2:35 pmWelcome and Introduction to workshop organisers:• MoxMonsters’ pipeline and offerings • Formlabs • Eye-2-Eye2:35 pm — 2:55 pmIntroduction: A Short History of Toy ManufacturingFrom garage kits & sofubi → CNC/steel tooling → resin kits → 3D printing (AM) → hybrid AM + low-pressure injection (SiOCAST) for market-fit pilots.2:55 pm — 3:15 pmProduction showcase for mold makingGoal: Showcase why formlabs is the 3d printer of choice for making masters for mass production Hands-on session: Allowing visitors to try sanding using regular resin printers3:15 pm — 3:25 pmPrint Optimisation & SlicingDesign for printability, speed, and downstream finishing.3:25 pm — 3:55 pmFull ecosystem ShowcaseSharing: a) Formlabs + MoxMonsters “Used-Cases” b) Siocast mass production use case. Creation of toys which will be launched in Singapore c) How small companies can use merchandise as effective marketing3:55 pm — 4:00 pmQuestions & Answers -

09:30 am — 12:00 pmAM Innovation with EOS2 Woodlands Sector1 #05-09 Woodlands Spectrum 1 S(738068)This workshop will explore how to significantly improve part buildability, increase overall productivity, and reduce cost per part using the latest innovations from EOS—Smart Fusion and Beam Shaping. These technologies represent key advancements in metal additive manufacturing, enabling more reliable, efficient, and cost-effective production. Participants will also gain insights into the critical success factors for copper printing, addressing challenges and best practices for achieving high-quality results with this demanding material. The session includes a guided tour of the EOS Technical Center, featuring live demonstrations of both metal and polymer systems: • Metal Systems: EOS M 290 and EOS M 400-4 • Polymer Systems: FORMIGA P 110 Velocis (×2) and EOS P 396 Demo parts will be on display to feature AM applications for different industries.Recommended for AM professionals, engineers, and decision makers.9:30 am — 9:40 amWelcome Note9:40 am — 10:00 amThe benefit of Smart Fusion and Beam Shaping in AM production10:00 am — 10:30 amThe critical success factors in copper printing10:30 am — 11:00 amTea Break11:00 am — 12:00 pmTour of EOS AM Facility

09:30 am — 12:00 pmAM Innovation with EOS2 Woodlands Sector1 #05-09 Woodlands Spectrum 1 S(738068)This workshop will explore how to significantly improve part buildability, increase overall productivity, and reduce cost per part using the latest innovations from EOS—Smart Fusion and Beam Shaping. These technologies represent key advancements in metal additive manufacturing, enabling more reliable, efficient, and cost-effective production. Participants will also gain insights into the critical success factors for copper printing, addressing challenges and best practices for achieving high-quality results with this demanding material. The session includes a guided tour of the EOS Technical Center, featuring live demonstrations of both metal and polymer systems: • Metal Systems: EOS M 290 and EOS M 400-4 • Polymer Systems: FORMIGA P 110 Velocis (×2) and EOS P 396 Demo parts will be on display to feature AM applications for different industries.Recommended for AM professionals, engineers, and decision makers.9:30 am — 9:40 amWelcome Note9:40 am — 10:00 amThe benefit of Smart Fusion and Beam Shaping in AM production10:00 am — 10:30 amThe critical success factors in copper printing10:30 am — 11:00 amTea Break11:00 am — 12:00 pmTour of EOS AM Facility 09:30 am — 01:30 pmLearning Journey with Singapore Poly and ASTM – Building capability in AM for Engineering and Built Environment with focus on Standards, Innovations & Industrial ApplicationsSingapore Polytechnic, 500 Dover Road, Singapore 139651Singapore Poly and ASTM International are co-organising a half-day workshop to engage industry practitioners with deep knowledge sharing and demonstrations in metal additive manufacturing and large-format pellet extrusion additive manufacturing. This workshop is jointly hosted by the School of Mechanical & Aeronautical Engineering (MAE) and the School of Architecture and Built Environment (ABE). Highlights of this workshop will include expert contributions from ASTM International, hands-on demos, and networking opportunities. Participants will have a chance to see a large format robotic arm in action and bring home a 3D-printed souvenir.Recommended for manufacturing industry practitioners, AM engineers, AM technologist, product designers, built environment and architectural practice professionals9:20 am — 9:30 amRegistrationParticipants to meet at Singapore Poly, W12019:30 am — 11:00 amPART 1: Metal Additive Manufacturing for Engineering Industry11:00 am — 11:10 amTransfer to School of Architecture and Built Environment (ABE)One-way transfer shuttle will be provided11:15 am — 1:30 pmPART 2: Large-Format Pellet Extrusion Additive Manufacturing for Construction

09:30 am — 01:30 pmLearning Journey with Singapore Poly and ASTM – Building capability in AM for Engineering and Built Environment with focus on Standards, Innovations & Industrial ApplicationsSingapore Polytechnic, 500 Dover Road, Singapore 139651Singapore Poly and ASTM International are co-organising a half-day workshop to engage industry practitioners with deep knowledge sharing and demonstrations in metal additive manufacturing and large-format pellet extrusion additive manufacturing. This workshop is jointly hosted by the School of Mechanical & Aeronautical Engineering (MAE) and the School of Architecture and Built Environment (ABE). Highlights of this workshop will include expert contributions from ASTM International, hands-on demos, and networking opportunities. Participants will have a chance to see a large format robotic arm in action and bring home a 3D-printed souvenir.Recommended for manufacturing industry practitioners, AM engineers, AM technologist, product designers, built environment and architectural practice professionals9:20 am — 9:30 amRegistrationParticipants to meet at Singapore Poly, W12019:30 am — 11:00 amPART 1: Metal Additive Manufacturing for Engineering Industry11:00 am — 11:10 amTransfer to School of Architecture and Built Environment (ABE)One-way transfer shuttle will be provided11:15 am — 1:30 pmPART 2: Large-Format Pellet Extrusion Additive Manufacturing for Construction 02:00 pm — 05:00 pmFunction-Driven Generative Design for Optimized Lightweight Structures in Additive ManufacturingSEACAD Training Academy, 28 Genting Lane, #01-03, Singapore 349585Discover how to leverage cutting-edge technology to create lightweight, high-performance structures optimized for Additive Manufacturing (AM). This workshop will guide you through the power of function-driven generative design—transforming engineering intent into optimal geometries using advanced simulation and design automation tools.Recommended for design engineers, AM specialists, simulation engineers2:00 pm — 2:15 pmRegistration2:15 pm — 2:25 pmWelcome & Introduction to Function-Driven Generative Design2:25 pm — 2:45 pmGenerative Design Principles & Workflow2:45 pm — 3:10 pmValidation of Initial and Final Designs Using SIMULIA Abaqus FEA3:10 pm — 3:30 pmTea break3:30 pm — 4:30 pmHands-on session4:30 pm — 5:00 pmQuiz & Q&A

02:00 pm — 05:00 pmFunction-Driven Generative Design for Optimized Lightweight Structures in Additive ManufacturingSEACAD Training Academy, 28 Genting Lane, #01-03, Singapore 349585Discover how to leverage cutting-edge technology to create lightweight, high-performance structures optimized for Additive Manufacturing (AM). This workshop will guide you through the power of function-driven generative design—transforming engineering intent into optimal geometries using advanced simulation and design automation tools.Recommended for design engineers, AM specialists, simulation engineers2:00 pm — 2:15 pmRegistration2:15 pm — 2:25 pmWelcome & Introduction to Function-Driven Generative Design2:25 pm — 2:45 pmGenerative Design Principles & Workflow2:45 pm — 3:10 pmValidation of Initial and Final Designs Using SIMULIA Abaqus FEA3:10 pm — 3:30 pmTea break3:30 pm — 4:30 pmHands-on session4:30 pm — 5:00 pmQuiz & Q&A 02:00 pm — 04:00 pmThe Evolving Role of Computed Tomography in Additive Manufacturing30,32 Kian Teck Road, Singapore 628779The workshop will cover: - Demonstration of basic and advanced CT techniques, and customized methods used to overcome the challenges of complex geometries and features in additively manufactured components. - Discover how Hexagon's Volume Graphics software empower quantitative and qualitative evaluation of AM samples through CT scan data — from porosity analysis and dimensional validation to reverse engineering and mesh compensation.Recommended for AM designers, engineers, and professionals.2:00 pm — 2:15 pmIntroduction2:15 pm — 3:45 pmCT Demonstration and Hexagon Introduction & Solutions3:45 pm — 4:00 pmFacility Tour

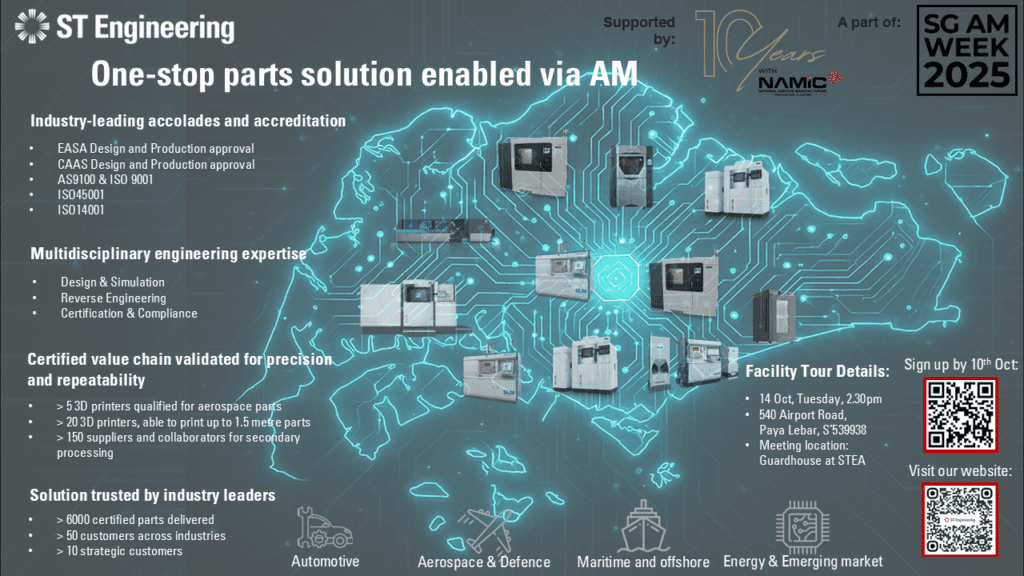

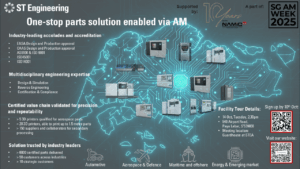

02:00 pm — 04:00 pmThe Evolving Role of Computed Tomography in Additive Manufacturing30,32 Kian Teck Road, Singapore 628779The workshop will cover: - Demonstration of basic and advanced CT techniques, and customized methods used to overcome the challenges of complex geometries and features in additively manufactured components. - Discover how Hexagon's Volume Graphics software empower quantitative and qualitative evaluation of AM samples through CT scan data — from porosity analysis and dimensional validation to reverse engineering and mesh compensation.Recommended for AM designers, engineers, and professionals.2:00 pm — 2:15 pmIntroduction2:15 pm — 3:45 pmCT Demonstration and Hexagon Introduction & Solutions3:45 pm — 4:00 pmFacility Tour 02:30 pm — 04:00 pmFuture of Manufacturing at ST Engineering’s Additive Manufacturing Centre of Excellence540 Airport Road, Paya Lebar, S539938. Meeting point: Guard House at STEACurious about what is inside the Centre of Excellence for additive manufacturing at ST Engineering? This tour will give an overview of our AM capabilities, which are able to produce certifiable end use products for our customers. We will also be showcasing some of our developed applications in Automotive, Aerospace & Defence, Maritime and Offshore and Energy & Emerging markets. Further, we will be giving a glimpse into the vigorous control that enabled us to gain recognition for our production process for printing certified parts for aviation industry and more.Recommended for users / product owners who are looking for AM solutions, engineers developing AM solutions, or management looking to adopt AM2:30 pm — 2:35 pmMeetingMeeting at Guard House2:35 pm — 3:05 pmApplications showcase30 mins overview and application showcase3:05 pm — 3:25 pmQ&AQuestions and Answers session3:25 pm — 3:45 pmFacility TourTour of STEA Facility and Centre of Excellence

02:30 pm — 04:00 pmFuture of Manufacturing at ST Engineering’s Additive Manufacturing Centre of Excellence540 Airport Road, Paya Lebar, S539938. Meeting point: Guard House at STEACurious about what is inside the Centre of Excellence for additive manufacturing at ST Engineering? This tour will give an overview of our AM capabilities, which are able to produce certifiable end use products for our customers. We will also be showcasing some of our developed applications in Automotive, Aerospace & Defence, Maritime and Offshore and Energy & Emerging markets. Further, we will be giving a glimpse into the vigorous control that enabled us to gain recognition for our production process for printing certified parts for aviation industry and more.Recommended for users / product owners who are looking for AM solutions, engineers developing AM solutions, or management looking to adopt AM2:30 pm — 2:35 pmMeetingMeeting at Guard House2:35 pm — 3:05 pmApplications showcase30 mins overview and application showcase3:05 pm — 3:25 pmQ&AQuestions and Answers session3:25 pm — 3:45 pmFacility TourTour of STEA Facility and Centre of Excellence -

02:00 pm — 05:00 pmRevealing Hidden Environmental Costs in Metal AM Through Life Cycle AssessmentKinesis @ Fusionopolis, Seminar Room 2, 4 Fusionopolis Way, Level 6, S138635Unlocking innovations in industrial applications, Metal Additive Manufacturing (AM) is transforming how high-performance components are designed, produced, and repaired. The expansion of metal AM in industry raises important, yet unanswered, questions about its environmental sustainability. While it promises material efficiency and reduced waste, the energy intensity, powder production methods, and post-processing requirements raise important environmental trade-offs. Life Cycle Assessment (LCA) provides a science-based framework to evaluate these trade-offs—quantifying environmental impacts from raw material extraction to end-of-life, including complex post-processing and support removal. This seminar will equip participants with the tools and insight needed to make informed, sustainability-driven decisions in metal AM. Together, we will explore how LCA can present both risks, such as gaps in data and modelling complexities, and rewards, including leveraging robust environmental insights for better design and qualification strategies.Recommended for AM engineers and professionals with interest in sustainability and cost efficiency, ESG and lifecycle strategy teams within manufacturing enterprises, product and innovation managers exploring AM for high performance parts, academics and technology developers advancing sustainability metrics for AM1:30 pm —Registration

02:00 pm — 05:00 pmRevealing Hidden Environmental Costs in Metal AM Through Life Cycle AssessmentKinesis @ Fusionopolis, Seminar Room 2, 4 Fusionopolis Way, Level 6, S138635Unlocking innovations in industrial applications, Metal Additive Manufacturing (AM) is transforming how high-performance components are designed, produced, and repaired. The expansion of metal AM in industry raises important, yet unanswered, questions about its environmental sustainability. While it promises material efficiency and reduced waste, the energy intensity, powder production methods, and post-processing requirements raise important environmental trade-offs. Life Cycle Assessment (LCA) provides a science-based framework to evaluate these trade-offs—quantifying environmental impacts from raw material extraction to end-of-life, including complex post-processing and support removal. This seminar will equip participants with the tools and insight needed to make informed, sustainability-driven decisions in metal AM. Together, we will explore how LCA can present both risks, such as gaps in data and modelling complexities, and rewards, including leveraging robust environmental insights for better design and qualification strategies.Recommended for AM engineers and professionals with interest in sustainability and cost efficiency, ESG and lifecycle strategy teams within manufacturing enterprises, product and innovation managers exploring AM for high performance parts, academics and technology developers advancing sustainability metrics for AM1:30 pm —Registration -

08:30 am — 05:30 pmGlobal AM Summit

08:30 am — 05:30 pmGlobal AM SummitThe NAMIC Global Additive Manufacturing Summit (GAMS) returns for its 14th edition this year! Co-located with Industrial Transformation Asia-Pacific – a Hannover Messe Event, GAMS is Singapore’s flagship in-person AM business event, bringing together global thought leaders, entrepreneurs, and leading AM application experts.

Themed “Unlocking Agility and Scale with Digitalisation and Additive Manufacturing”, this year’s summit will feature topics on how additive manufacturing and digital technologies are transforming industries, enabling scalable production, and driving circular economy manufacturing.

08:30 amRegistration

09:30 amOpening Remarks

09:35 amWelcome Address

Dr Ho Chaw Sing

Chief Executive Officer, NAMIC09:45 amOpening Address by Guest-of-Honour

Mr Beh Kian Teik

Chief Executive Officer, Agency for Science, Technology and Research (A*STAR)

09:55 amAnnouncement of Memorandum of Understanding, Partnerships and Alliance

10:10 amAgility and Scaling of AM: Are Both Achievable?

Dr Terry Wohlers

Distinguished Fellow of Advanced Manufacturing, Wohlers Associates, powered by ASTM International

10:30 amTea Break

Additive Manufacturing: A Global Outlook

As global manufacturing grapples with escalating trade tensions and the resurgence of protectionist policies, the additive manufacturing industry faces both unprecedented challenges and transformative opportunities. Recent tariff hikes have disrupted supply chains and increased production costs, prompting companies to re-evaluate their sourcing strategies and explore localised manufacturing solutions. In this complex landscape, the session will convene experts from various regions to share insights into how their local ecosystems are navigating these dynamics. Discussions will encompass regional advancements, policy responses, and the strategic integration of additive manufacturing to enhance resilience and competitiveness in the face of global economic shifts.

11:00 amOpening for Session

Mr Joris Peels

Vice President Consulting, Additive Manufacturing Research11:05 amCan Additive Manufacturing Rebuild Resilience in a Disrupted Global Trade Landscape?

Moderator

Mr Joris Peels, Vice President Consulting, Additive Manufacturing ResearchPanelists

1. Dr Terry Wohlers, Distinguished Fellow of Advanced Manufacturing, Wohlers Associates, powered by ASTM International

2. Mr Matthias Schmidt-Lehr, Managing Partner, AMPOWER

3. Dr Jeanne Ong, Director of Ecosystem and Internationalisation, NAMIC

4. Dr Ehsan Toyserkani, Director, Multi-Scale Additive Manufacturing Lab

5. Ms Kitty Wang, Founder, 3D Science Valley12:00 pmLunch

Agile & Distributed Manufacturing with AM

In an era marked by geopolitical volatility, supply chain disruptions, and shifting consumer demands, agility has become a strategic imperative for manufacturers. The session will explore how additive manufacturing empowers decentralised production models to enhance responsiveness and resilience and enables organisations to adopt “glocalized” manufacturing strategies—producing on-demand closer to the point of need while adhering to quality standards. This session will feature real-world case studies and expert insights on how distributed manufacturing with additive manufacturing is reshaping supply chain strategies and future-proofing operations.

01:00 pmOpening for Session

Dr Terry Wohlers

Distinguished Fellow of Advanced Manufacturing, Wohlers Associates, powered by ASTM International01:05 pmReshaping the Future of Aerospace Production with Additive Manufacturing

Mr Nicholas Mulé

Director of Additive Manufacturing, Boeing01:20 pmNavigating through Evolving Demands of a Highly Regulated Industry

Mr Shri Shetty

Chief Executive Officer, OIC International

01:35 pmMass Production of Next Generation 3D-Printed Electronics

Mr Jim Golden

Vice President of Sales and Marketing, Fabric8Labs01:50 pmRedefining Readiness and Supply Chain Resilience at ST Engineering

Mr Benjamin Moey

Vice President of New Ventures, ST Engineering

02:05 pmTransforming Supply Chains with Additive Manufacturing: Building Resilient, Scalable, and Glocalized Production Ecosystems

Moderator

Dr Terry Wohlers, Distinguished Fellow of Advanced Manufacturing, Wohlers Associates, powered by ASTM InternationalPanelists

1. Mr Nicholas Mulé, Director of Additive Manufacturing, Boeing

2. Mr Shri Shetty, Chief Executive Officer, OIC International

3. Mr Jim Golden, Vice President of Sales and Marketing, Fabric8Labs

4. Mr Benjamin Moey, Vice President of New Ventures, ST Engineering02:50 pmTea Break

Digital Workflows for Smart Manufacturing

As the production environment evolves into smart and more connected systems, additive manufacturing is playing a pivotal role in enabling end-to-end digital workflows—from AI-driven design and generative engineering to digital twins and real-time process monitoring. This session will explore how additive manufacturing is seamlessly integrating into the broader wave of industry digital transformation, highlighting how additive manufacturing systems, powered by data and machine learning, are unlocking new levels of customisation, scalability, and operational intelligence, laying the foundation for an intelligent manufacturing future.

03:20 pmOpening for Session

Dr David Rosen

Principal Scientist, A*STAR Institute of High Performance Computing & Singapore Institute of Manufacturing Technology03:25 pmEnabling Secure, Decentralized Manufacturing Through Digital Workflow Orchestration

Mr Lior Polak

Chief Executive Officer & Co-founder, Assembrix03:40 pmFrom Data to Decisions: Orchestrating Agile Manufacturing with Authentise Workflows

Mr Andre Wegner

Chief Executive Officer, Authentise03:55 pmModernising Maritime and Energy Supply Chains: The Shift from Physical Inventory to On-Demand Digital Manufacturing

Mr Scott Harding

Vice President of Engineering, Pelagus 3D04:10 pmOn-Demand, On-Time: Redefining Custom Part Production with a Fully Digital, Scalable, and Supplier-Agnostic Manufacturing Ecosystem

Mr Hardik Dobariya

Co-Founder and Chief Product Officer, Factorem04:25 pmFrom Design to Delivery: Building a Seamless Digital Thread

Moderator

Dr David Rosen, Principal Scientist, A*STAR Institute of High Performance Computing & Singapore Institute of Manufacturing TechnologyPanelists

1. Mr Lior Polak, Chief Executive Officer & Co-founder, Assembrix

2. Mr Andre Wegner, Chief Executive Officer, Authentise

3. Mr Scott Harding, Vice President of Engineering, Pelagus 3D

4. Mr Hardik Dobariya, Chief Product Officer & Co-founder, Factorem05:10 pmEnd of Summit Day 1

-

9:00 am — 02:30 pmGlobal AM Summit

9:00 am — 02:30 pmGlobal AM SummitThe NAMIC Global Additive Manufacturing Summit (GAMS) returns for its 14th edition this year! Co-located with Industrial Transformation Asia-Pacific – a Hannover Messe Event, GAMS is Singapore’s flagship in-person AM business event, bringing together global thought leaders, entrepreneurs, and leading AM application experts.

Themed “Unlocking Agility and Scale with Digitalisation and Additive Manufacturing”, this year’s summit will feature topics on how additive manufacturing and digital technologies are transforming industries, enabling scalable production, and driving circular economy manufacturing.

09:00 amRegistration

09:30 amFrom Atoms to Applications: Building an AI-Driven Materials Discovery Platform

Dr Maksym Plakhotnyuk

Founder & Chief Executive Officer, ATLANT 3DScaling AM: Bridging the Gap Between Innovation and Industrialisation

While additive manufacturing has demonstrated immense potential in prototyping and customised production, scaling it for high-volume industrial use remains a complex challenge. This session will examine what it takes to move additive manufacturing from cutting-edge innovation to widespread industrial adoption, spotlighting real-world case studies across sectors and highlighting the challenges that companies need to overcome when scaling additive manufacturing technologies. From overcoming material and certification constraints to building robust supply ecosystems, this session will uncover what’s needed to close the gap between promise and production.

09:50 amOpening for Session

Mr Matthias Schmidt-Lehr

Managing Partner, AMPOWER09:55 amReal-World Challenges in Scaling Additive Manufacturing: HP’s Solutions Across Diverse Industries

Mr Alex Moñino

Senior Vice President & General Manager, HP Additive Manufacturing Solutions10:10 amBuilding Scalable Additive Manufacturing Production

Mr Eddie Andrews

Commercial Director, 3T Additive Manufacturing10:25 amAccelerating Precision and Scale in Metal Additive Manufacturing

Dr Behrang Poorganji

Vice President of Technology, Nikon Advanced Manufacturing Inc.10:40 amDriving Industrial Metal Additive Manufacturing Through Vertical Integration

Mr Vincent Yang

General Manager, BLT Shenzhen10:55 amAre We Really Ready to Manufacture Differently?

Moderator

Mr Matthias Schmidt-Lehr, Managing Partner, AMPOWERPanellists

1. Mr Alex Monino, Senior Vice President & General Manager, HP Additive Manufacturing Solutions

2. Mr Eddie Andrews, Commercial Director, 3T Additive Manufacturing

3. Dr Behrang Poorganji, Vice President of Technology, Nikon Advanced Manufacturing Inc.

4. Mr Vincent Yang, General Manager, BLT Shenzhen11:40 amLunch

The Role of AM in Sustainability

As manufacturers strive to reduce their environmental impact, additive manufacturing offers significant advantages in material efficiency, energy usage, and waste reduction. This session will explore how additive manufacturing supports decarbonization goals and delve into additive manufacturing’s contributions to the circular economy, including the reuse and recycling of materials, as well as innovations in bio-based and low-impact materials. From design to end-of-life, this session will showcase how additive manufacturing is helping industries build cleaner, more responsible manufacturing systems for the future.

12:40 pmOpening for Session

Mr Kelvin Zin

Director, A*STAR Science & Engineering Research Council (SERC)12:45 pmPrinted Shoes on Every Foot

Mr Lennard Stoever

Co-founder & President, Zellerfeld Shoe Company Inc.01:00 pmFrom Waste to Wall Transforming Construction Materials

Dr Du Hongjian

Co-founder, Circrete01:15 pmUnlocking Transformative Water Filtration Technology with Additive Manufacturing

Mr Andrew Walker

Chief Commercial Officer, Evove

01:30 pmLeveraging Additive Manufacturing for Clean Energy Infrastructure

Mr Mason Bell

Anchor Lead, Sperra01:45 pmCan Additive Manufacturing Truly Deliver on the Promise of Sustainable Industry?

Moderator

Mr Kelvin Zin, Director, A*STAR Science & Engineering Research Council (SERC)Panellists

1. Mr Lennard Stoever, Co-founder & President, Zellerfeld Shoe Company Inc.

2. Dr Du Hongjian, Co-founder, Circrete

3. Mr Andrew Walker, Chief Commercial Officer, Evove

4. Mr Mason Bell, Anchor Lead, Sperra02:30 pmEnd of Day 2

End of Summit

Cookie Consent

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Cookie Preferences

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

Google reCAPTCHA helps protect websites from spam and abuse by verifying user interactions through challenges.

These cookies are used for managing login functionality on this website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)