-

The NAMIC Global Additive Manufacturing Summit returns with its first in-person edition after two years of pandemic impacts and restrictions. Held in conjunction with the Industry Transformation ASIA-PACIFIC – a Hanover Messe event (ITAP) 2022, the leading Industry 4.0 exhibition in Southeast Asia dedicated to advanced manufacturing and all of its related technologies.

Global Additive Manufacturing Summit will provide a one-stop learning and networking platform for students, industry professionals, and innovators along the entire AM value chain, looking to adopt additive manufacturing.

Themed “Embracing sustainability and supply chain resilience with 3D printing”, the two-day summit will discuss topics on decarbonisation and supply chain resilience through additive manufacturing. Under the Singapore Manufacturing 2030 vision together with Artificial Intelligence, and Robotics will form the cornerstone in enabling Industry 4.0 transformation, translate and commercialise 3D Printing technologies, and Digital Manufacturing in a Digital Economy.

*Virtual Passes available.

Top Reasons to Attend

- Soak up the wealth of experience of our world class speakers

- Experience ground-breaking technological developments across Industries

- Gain insights into success stories of AM start-ups

- Network with over 300 local & international delegates

Global Additive Manufacturing Summit 2022 – At a Glance

Key Topics – What to Expect

Enabling a Sustainable Future with Additive Manufacturing:

- Empowering a Sustainable World

- Resilience in our Supply Chains

- Transforming Lives and Humanity

Who to Attend?

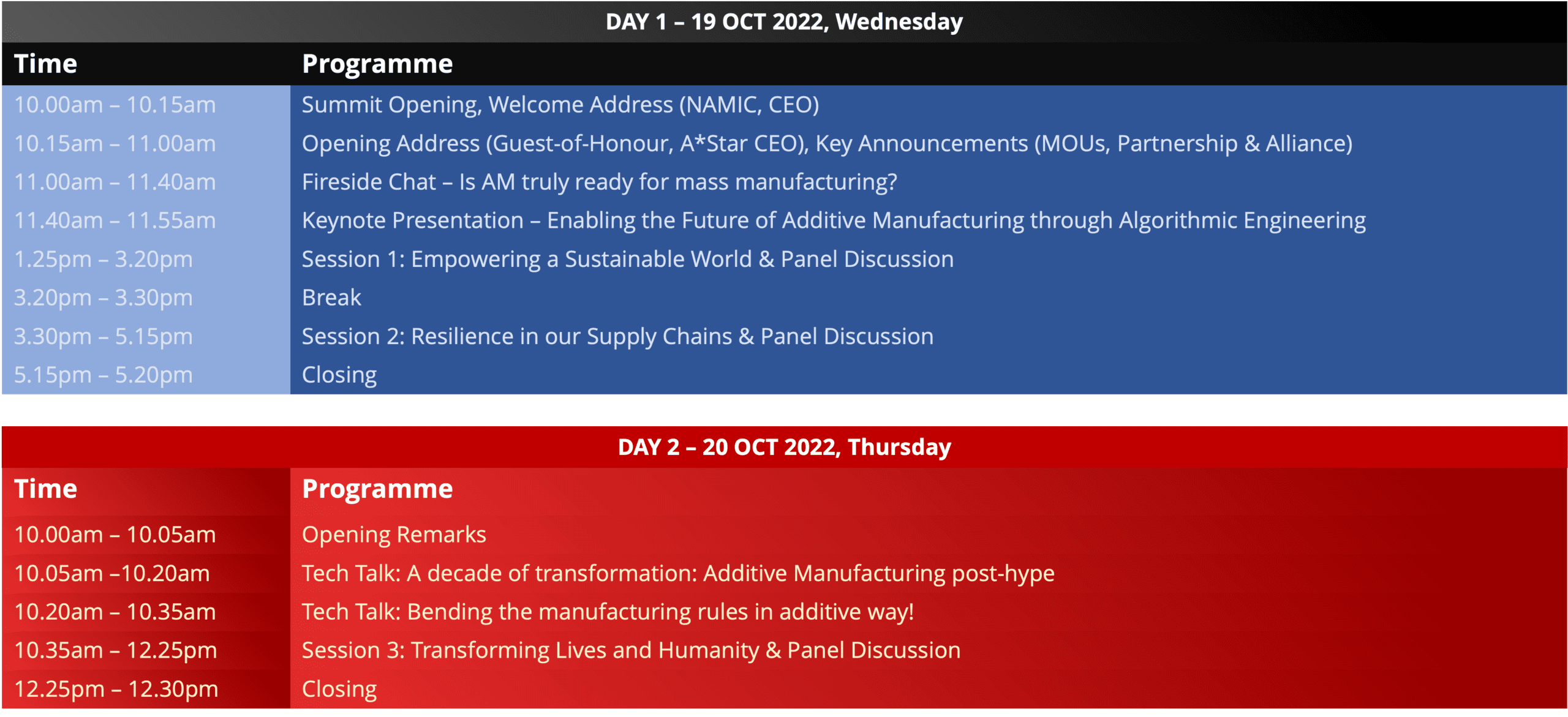

Summit Programme

Video Archive

Day 1

Day 2

*All timings stated in SGT

Contact Us

For any enquiries, please contact:

Ms Christle Koh, Head of Events & Marketing

ITAP 2022

-

Time Programme Wednesday, 19 October 2022, Day 1

10:00 am Opening Remarks

Emcee

10:05 am Welcome Address

Dr. Ho Chaw Sing, Chief Executive Officer, NAMIC

10:15 am Opening Address by Guest-of-Honour

Mr. Frederick Chew, Chief Executive Officer, A*STAR

10:30 am Announcement of Memorandum of Understanding, Partnerships and Alliance

- Launch of Molyworks Materials Corporation Singapore Foundry

- MOU between Printerprezz, Singapore Health Services, National Healthcare Group, National University Health Systems and National Additive Manufacturing Innovation Cluster

- MOU between ST Engineering Land Systems and ASTM International AM Center of Excellence

11:00 am Fire-side Chat: Is Additive Manufacturing truly ready for Mass Manufacturing?

Joris Peels, VP, 3DPrint.com and

Dr. Kevin Slattery, Principal ADDvisor, The Barnes Global Advisors

11:40 am Keynote Presentation – Enabling the Future of Additive Manufacturing through Algorithmic Engineering

Linhan Wu, Ambassador, Hyperganic Group11:55 am Networking Lunch

Session 1: Empowering a Sustainable World

01:25 pm Transition to speakers presentation

01:30 pm Presentation – Enabling Repair Capability towards a Sustainable Future

Iain Rodger, MD, GE Aviation Singapore01:50 pm Presentation – 3D Printed Construction: A Key Tool for a Sustainable Future

Sam Ruben, Co-founder/Senior Sustainability Officer, Mighty Buildings Inc02:10 pm Presentation – Disrupt AM limitation with Materials designed for AM

Dr. Yusaku Maruno, General Manager, Hitachi Metals Ltd.02:30 pm Panel Discussion – How can AM accelerated sustainability?

Moderator: Joris Peels

Panelists: Iain Rodger, Sam Ruben, Dr. Yusaku Maruno03:20 pm Break

SESSION 2: Resilience in our Supply Chains

03:30 pm Presentation – Alleviating Bottlenecks in the AM Value Chain : Testing & Certification

Guillaume Mohara, Technical Manager, Cetim03:50 pm Presentation – AM powering the Agility in Supply Chain

Catherine Soo, Vice President of Contract Logistics, DB Schenker Singapore04:10 pm Presentation – Rethinking Distributed Manufacturing Supply Chain

Abhinav Singhal, VP & Head of Strategy, SAP Asia Pacific & Japan04:30 pm Panel Discussion – Can AM enable more Resilient Supply Chains; and if so, how would that Impact Trade?

Moderator: Dr. Kevin Slattery

Panelists: Guillaume Mohara, Catherine Soo, Abhinav Singhal05:15 pm Closing of Day 1

Thursday, 20 October 2022, Day 2

10:00 am Opening Remarks

Emcee10:05 am Tech Talk: A decade of transformation: Additive Manufacturing post-hype

Daniel O’Connor, VP Content Strategy & New Product Development, Rapid News Group10:20 am Tech Talk: Bending the Manufacturing Rules in Additive Way!

Peter Rogers, Director of Business Development APAC, Velo3DSESSION 3: Transforming Lives and Humanity

10:35 am Transition to speakers presentation

10:40 am Presentation – Wonderful Sound for All through Additive Manufacturing

Lee Yik Bin, Senior Director Research Development, WSAudiology11:00 am Presentation – Transforming our Environment into Arts through AM

A. Professor Carlos Bañón, Co-Founder, SUBARQUITECTURA Architects & SUTD AIRLAB11:20 am Presentation – Circular Economy: Paving the way towards Net Zero with Additive Manufactured Filtration Technology

Liu Kangsheng, VP Innovation, Evove11:40 am Panel Discussion – How can AM improve our society?

Moderator: Peter Rogers

Panelists: Lee Yik Bin, Carlos Banon, Liu Kangsheng12:25 pm Closing of Day 2

-

A. Professor Carlos Bañón

Co-Founder, SUBARQUITECTURA Architects & SUTD AIRLAB

Catherine Soo

Vice President of Contract Logistics, DB Schenker SingaporeCatherine Soo

Catherine is the Vice President of Schenker Singapore (Pte) Ltd, overseeing Logistics operation, Air Freight, Ocean Freight, across 10 verticals, covering 13 facilities with 2.9 Mio Sq ft warehouse footprint.

Before joining Schenker 6 years ago, Catherine has held senior Global, Regional and Country roles at the world’s largest automaker for 19 years, majoring in Supply Chain strategy and dynamics. She was heavily immersed in the supply chain challenge at Joint Venture in China in early 2000. In her Global role in Germany, she specifically specializing in optimizing material flow of 122 production plants worldwide.

Catherine is knowledgeable, versatile, and well-experienced in formulating solutions. She promotes sustainability and adoption of new technology in the organization to bring the best value for her people and customer. With foresight in identifying opportunities, she also plays a key role in business strategy formation and sustainable leadership development. She is the Industry Board member of SUTD ESD Department and Ministry of Transport Future Economic Committee Member.

Daniel O'Connor

VP Strategy & New Product Development, Rapid News GroupDaniel O'Connor

Daniel began his career in additive manufacturing reporting for TCT Magazine in 2013 and is currently responsible for the content strategy at Rapid News Group – a media and events organisation specialising in engineering.

Guillaume Mohara

Technical Manager, Cetim

Iain Rodger

MD, GE Aviation SingaporeIain Rodger

Iain Rodger is Managing Director, GE Aviation Engine Services – Singapore Pte Ltd (GEAESS), part of GE Aviation, the world’s leading provider of aircraft jet and turboprop engines and aircraft systems.

In his role, Iain is responsible for leadership and strategic direction of GEAESS’ 2000 employees at their three facilities in Singapore. These facilities operate at the forefront of aircraft engine manufacturing & repair technologies.

Iain joined GE Aviation in 2019 as Managing Director of GE’s Maintenance, Repair & Overhaul (MRO) plant in Prestwick, Scotland, successfully leading the team there through a difficult period in the aviation industry. Iain is a manufacturing engineer by profession, and an accomplished global supply chain leader.

Prior to joining GE Aviation, Iain spent over thirty years in various executive roles at Rolls- Royce, in the United Kingdom, Germany, Japan and China. He was accountable for the integration of the Fans and Compressor supply chain operational functions globally across manufacturing, purchasing, planning and control, quality, and environment, health & safety.

Iain holds a Bachelor of Engineering degree in Manufacturing Systems with Electronics from Glasgow Caledonian University and is an alumnus of the University of Cambridge’s Manufacturing Leaders Programme (MLP).

Iain is a strong supporter and advocate of STEM education outreach activities.

In his personal capacity, he takes a keen interest in rugby union football and poetry. Iain is married with a son and daughter.

Joris Peels

VP, 3DPrint.com

Liu Kangsheng

VP Innovation, EvoveLiu Kangsheng

Since 2020, Kangsheng has been leading the technological and scientific directions of Evove as VP of Innovation. Through his leadership, he has helped the business diversify commercial offerings to new applications, e.g. Kangsheng has led the development of the first direct lithium extraction solution from scratch to commercial validation, taking Evove to the forefront of this emerging and fast-growing market, creating substantial growth opportunity. Kangsheng has helped build the Additive Manufacturing part of the business through his background in advanced materials and processing.

Prior to his current role, Kangsheng was leading the R&D department in G2O Water Technologies (later Evove). He led the development of the first graphene coating solution from scratch to commercial validation in the water industry. It has helped create a pipeline of new customers and significantly lifted the business’s growth prospects.

Kangsheng first became interested in advanced materials after his undergraduate in Bio- functional Materials from Beijing University of Chemical Technology. His interest in the advanced materials and technology encouraged him to pursue Masters and PhD degrees in Materials Science and Technology in the British Loughborough University. Afterwards, he took research fellow positions at a number of British Universities, e.g. University of Leeds, in the Russel Group, where he led research projects including water and advanced materials.

Fascinated by the technologies he developed and the need in the water industry, Kangsheng joined G2O Water Technologies to continue to pursue the desire to drive the development and commercial implementation of novel solutions to help empower the green transition to a net-zero society. Evove is pioneering the application of advanced additive manufacturing for filtration and separation applications using ceramic materials for the first generation of ultra-performance membranes.

Dr. Kevin Slattery

Principal ADDvisor, The Barnes Global AdvisorsDr. Kevin Slattery

Kevin T. Slattery, D.Sc is a Principal ADDvisor® at The Barnes Global Advisors. His primary expertise is in Metallic Additive and Metals Manufacturing, focusing on test program development, process and product verification, qualification, and certification.

He is a 2020 Ambassador for America Makes, and a member of the 2020 Materials Challenge Silver Medal team in the USAF Rapid Sustainment Office Additive Manufacturing Olympics.

Kevin was previously the Chief Scientist for AM and Metals in Boeing Research and Technology leading a multi-skilled team to deliver the technology throughout the company. He was a Division Chief Engineer in Boeing’s Military Sustainment group from 2012 to 2015. Prior to that, Kevin led the implementation of the first metal AM structural aircraft components. Additionally, he has 6 other first in the industry technology implementations. He holds B.S. and M.S. degrees in Metallurgical Engineering from Missouri S&T, and a D.Sc. in Material Science from Washington University. Kevin currently holds 39 US patents, with 13 applications pending.

Lin Kayser

CEO, HyperganicLin Kayser

Lin Kayser, is the co-founder and CEO of Hyperganic, a company radically transforming how we engineer and manufacture objects using A.I. and computer algorithms.

Kayser is a serial entrepreneur who started his first company at the age of 19.

In the 1990s, he helped pioneer industrial control systems based on PC technology with German tech startup ARADEX, now part of the Chinese WEICHAI Group.

In 2000, he started IRIDAS which quickly became the technological leader in high end image processing for the global movie industry. IRIDAS was acquired by US tech giant Adobe in 2011.

Peter Rogers

Director of Business Development APAC, Velo3DPeter Rogers

Peter Rogers, APAC Business Development Director at Velo3D since 2022. With a goal of helping businesses achieve strong results with additive manufacturing (AM), his role at Velo3D sees him engaging some of the top manufacturers in the Asia Pacific region and collaborating on development and execution of their joint growth plan. Whether it be through OEM’s in-house production planning or using the Velo3D contract manufacturing network, he always finds a way to deliver the best solutions to his customers.

Previously at Autodesk, Peter was the head of the AM cohort and was the regional product specialist from 2016 to 2022. His role entailed sales, business development and technical support in the APAC region for the Autodesk Netfabb and Fusion360 products. After Autodesk acquired Netfabb in 2015, he worked hard on the GTM strategy and was crucial in the fast growth achieved in the region. His journey into AM started with his Global Sales Director role at Kabuku Inc (Tokyo) where his strong results fueled the company’s growth, leading to a total of $10mil+ in venture capital fund raising.

Graduating from Swinburne University of Technology (Australia) International Business / Arts double degree, he’s been living in Tokyo for a total of 10 years. He is an active contributor and thought leader, and his strong industry presence earned him the nomination for Community Advocate of the Year award in 2021 at the 3D Printing Awards.

Sam Ruben

Co-founder/Senior Sustainability Officer, Mighty Buildings IncSam Ruben

A graduate of Vassar College & Presidio Graduate School, Sam Ruben is an accomplished innovator, entrepreneur, executive, and a co-founder at Mighty Buildings, a construction technology company based out of Oakland, California which is using 3D printing, new composite materials, and robotics to sustainably unlock productivity in construction. His passion and deep understanding of sustainability and compliance drew him to the vision to help solve the housing and climate crises by transforming the way the world builds homes.

As a part of Mighty Buildings’ founding team, Sam has leveraged his expertise working with organizations of all sizes across the public, private, and non-profit sectors to help them improve their sustainability in terms of people, planet, and prosperity to guide Mighty Buildings’ Certification & Sustainability roadmaps. This has resulted in Mighty Buildings producing the first UL-listed 3D-printed building component, being the first company certified under UL 3401 (new standard for 3DP in Construction), and the first housing unit utilizing 3D-printed components to be certified at the State level in California. Most recently Sam helped draft and lead the passage of AB 2446, the first bill in the United States to broadly address the embodied carbon in building materials. Using innovative material science, robotics and automation, Mighty Buildings is working to make carbon-neutral housing a reality for everyone.

Lee Yik Bin

Vice President, WSAudiologyLee Yik Bin

I am a mechanical engineer by training with passion in product development and product architecture. Since 2010, I have been in hearing aids industry where I could play a key role on how hearing aids can be designed differently from the traditional method. It is fulfilling to know that I can improve the quality of life for people suffering from hearing loss.

Prior to hearing aids industry, I have been involved in the R&D of mobile phone industry with Motorola for 11 years.

I am passionate about teamwork and believe that a good product can only be realized when all branches of engineering act together. This is one of the WS Audiology key values of “Going Beyond Together”.

I graduated in 1993 with Bachelor of Mechanical & Production Engineering in NTU. I also hold a Graduate Diploma in Business Administration (NUS) and Masters of BioMedical Engineering (NTU).

Dr. Yusaku Maruno

General Manager Global Research and Innovative Technology Centre (GRIT), Hitachi Metals Ltd.Dr. Yusaku Maruno

Dr. Maruno joined GRIT, Hitachi Metals Ltd. in April 2018 and was working as a senior researcher of Business Creation Department for creating an open innovation scheme on 3D additive manufacturing. He was transferred to Hitachi Metals Singapore (HMS), the regional business headquarters of Hitachi Metals in Asia Pacific, in October 2018, where he held the appointment of Senior Researcher to proceed the “Asia Business Expansion Project” initiated by Hitachi Metals headquarters in Japan, to develop new and sustainable business for Hitachi Metals group in the region. He has been the key project management member on the research collaboration projects with A*STAR research institutes namely SIMTech and IHPC for developing the 3D additive manufacturing related process technology and its computer simulation technology.

Since October 2020, he has been appointed the head of materials solution centre of Hitachi Metals Singapore, to conduct and promote open innovation including public-private collaboration on new materials and manufacturing related technology. Under his leadership, his centre implemented several kinds of collaborative activities in Singapore with 3D additive manufacturing related ecosystem and business partners.

Since July 2022, he has also been appointed the concurrent role of general manager of the Advanced Materials Development department in GRIT under Hitachi Metals, Ltd. In this new role, he is overseeing the development of innovative materials for a sustainable society with the aim to provide materials and process related solution that contribute to carbon neutrality, electrification, energy saving and mitigation of materials wastage.

Before joining Hitachi Metals Ltd., he was a senior researcher and unit leader of R&D team in materials research centre, centre for technology innovation, Hitachi Ltd. and had overseen materials development for sustainable energy. He has 18 years’ experience as scientist for metal materials development in Hitachi group from 2004. In 2013, he was working as visiting scientist in Massachusetts Institute of Technology in the US and managed collaborative research project of public-private collaboration on developing nuclear power and Oil&Gas related materials technology. After coming back to Japan, he was an affiliate scientist in MIT for 2 years and kept managing the US project with the scientists in MIT and concurrently working as a strategist in R&D planning department in the center for materials innovation, Hitachi Ltd.

Dr Maruno graduated from Doctoral Course of Kyushu University, Faculty of Materials Science and Engineering, Japan in March 2004.