Joint Industry Programme on AM Turbocharger Nozzle Ring for Maritime Industry

Key Information

AM Tech

Array Industry

Array Potential Applications

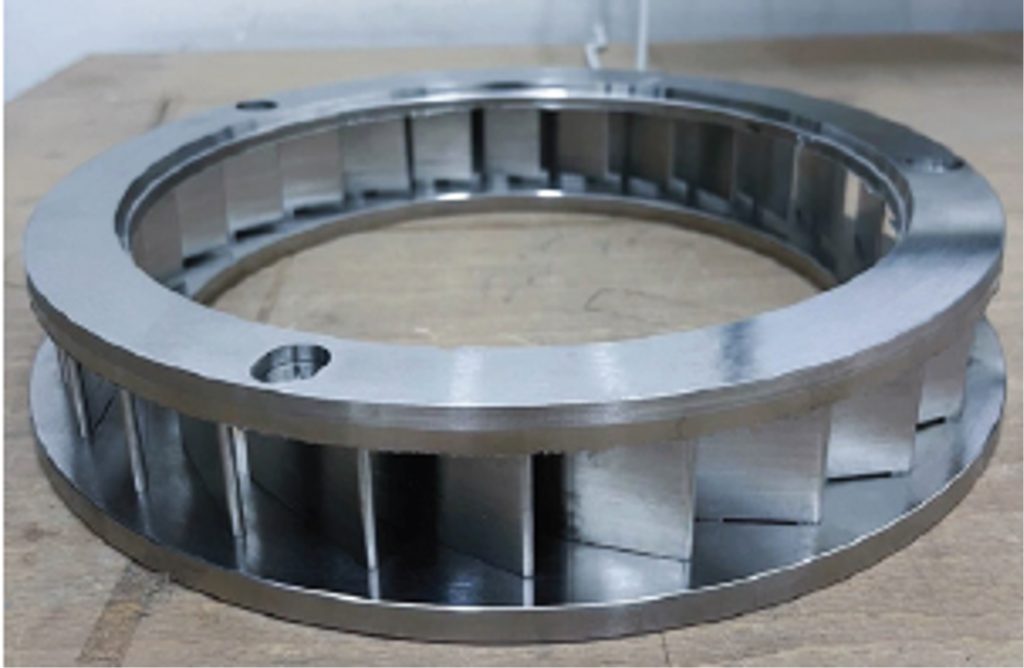

Qualified additive manufactured auxialiary engine turbocharger nozzle ring

Collaborators

The project is a consortium led by Lloyds Register, together with LRQA, 3D Metalforge, Singapore Polytechnic, Neptune Pacific Lines, Kompressorenbau Bannewitz GmbH and Professional Testing Services. Problem Statement

The nozzle ring is a part that operates under harsh conditions of high temperature and faces erosion and corrosion due to direct contact with engine exhaust flow. Regular maintenance of the nozzle ring is necessary but it is at the expense of downtime and lost efficiency. Procurement of a new part for replacement requires approximately six weeks of lead time, and inventory management of such high-value components requires precise planning.

Objective

To adopt AM to produce turbocharger nozzle rings so that the lifespan and performance of the part are optimised for ship vessels.

Key Benefits/Outcomes

- The project qualified the powder blown direct energy deposition (DED-LB) facility for fabricating the selected nozzle ring. It further demonstrated an efficient AM production workflow, starting from DED-LB process development to manufacturing, post-processing, inspection, testing and sea trial on board the container vessel, leading to a leaner production process.

- Singapore Polytechnic has also demonstrated the production of high-performance powder as AM feedstock via in-house gas atomisation facility.