Development of AM Gas Atomised Nickel Copper Aluminium Bronze Powder for Cold Spraying Process for Maritime Industry

Key Information

AM Tech

AM Metal Alloy Powder Industry

Maritime Potential Applications

Nickel aluminium bronze is the class approved material for maritime components such as propellers

Collaborators

NAMIC @ SP X Mencast Problem Statement

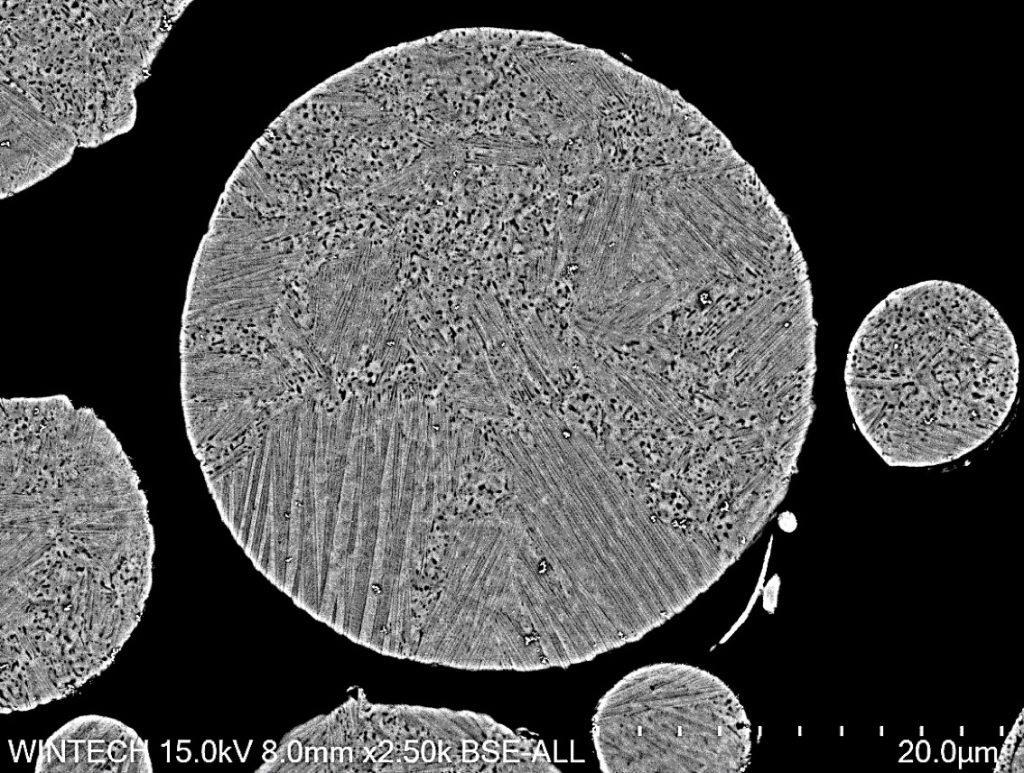

Nickel aluminium bronze is one of the important copper alloys for the maritime sector, for example, in the production of ship propellers. However, additive manufacturing processes of nickel aluminium bronze are still lacking adoption in this sector.

The feasibility of using nickel aluminium bronze powder for cold spraying process has not been proven.

Objective

- To develop a gas atomisation process for producing nickel aluminium bronze powder that meets the marine class requirement on the material properties.

- Investigate the feasibility of cold spraying copper alloy powder and heat treatment of the printed part to achieve the alloy requirement.

Key Benefits/Outcomes

- Developed the copper alloy powder for additive manufacturing cold spray process.

- Demonstrated gas atomisation is a scalable process for AM powder, which enables mass production of customised powders for cold spraying to meet the end-users’ demand in the maritime sector.

- Demonstrated cold spraying as a fast and scalable process for copper alloy.