Yamazaki Mazak was established in 1919 and has been contributing to the development of the machine tool industry as a leading global company. Yamazaki Mazak manufactures not only advanced machine tools such as multi-tasking centers, CNC turning centers, machining centers and laser processing machines, automation systems and the latest Hybrid multi-tasking machines with the concept of DONE IN ONE to support global manufacturing by providing exceptional productivity and versatility. Our Goal is to continuously develop new machine tools that meet today’s requirements and tomorrow’s vision.

YAMAZAKI MAZAK SINGAPORE PTE LTD

The Company

Products and Services

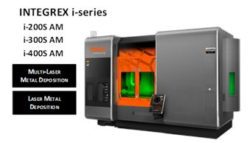

Mazak Hybrid Multi-Tasking Machine (Additive Manufacturing Series)

With the hybrid multi-tasking capabilities, manufacturers can generate or clad near-net-shape component features, paired with Mazak’s exceptional subtractive capabilities, completing a high-precision finish machining operation, all true to DONE IN ONE® part production.

- Produce parts in minimum amount of time, ideal for prototype component production.

- Deposit a different type of material (of a more expensive and higher quality material e.g. titanium) on a base material for versatility.

THREE AM TECHNOLOGIES

Multi-Laser metal deposition

DONE IN ONE machining of laser metal deposition processes required to increase the durability and strength of valves used in the aerospace and chemical industries as well as precision machining of molds and turbine blades can be performed.

Laser metal deposition

Expensive materials used in aerospace, energy and medical industries can be formed into near net shapes by laser metal deposition to reduce total production time. Additive manufacturing of different types of metals can be used for increased durability and anti-corrosiveness.

Wire ARC

Wire arc AM is suitable for a variety of processes, such as component near net shape, repair of molds and others.