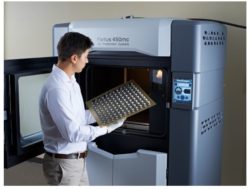

Additive Flight Solutions is a joint venture between SIA Engineering Company (SIAEC) and Stratasys. By utilising Stratasys’ deep knowhow and expertise in additive manufacturing, coupled with the comprehensive maintenance, repair and overhaul (MRO) at SIAEC, Additive Flight Solutions can provide Additive Manufactured aerospace part solutions to airline customers around the globe.

WE PRINT YOUR PARTS – fast, light, flexible

Additive Flight Solutions (AFS) aerospace certifications includes AS9100D, ISO9001:2015 and EASA POA Part 21G – EASA.21G.0080. AFS has produced more than 7,600 certified aviation parts and has a portfolio of 32 aircraft catalogue items for commercial and defense aviation.

We offer Printing on Demand and distributed manufacturing. We can produce large industrial aerospace tooling and have supplied aerospace companies including Safran, SIAEC, SAESL, Eagle Services Asia, incorporating weight savings, fast availability and better performance.

Visit the AFS website www.additiveflightsolutions.com for Manufacturing On Demand

On-shoring – the ability to move production closer to consumption and respond better to changes in demand.

Flexibility – to make one product on a machine one day and another the next, or to immediately improve a product by simply uploading a new CAD file.

Speed – to start producing parts immediately instead of waiting weeks or months for retooling or shipping.

Efficiency – to produce low-to-mid volumes of critical parts less expensively.

Time-to-market – to go from design to finished part ahead of the competition and far faster than ever before.

The short development and prototyping time is a typical feature of additive manufacturing. Designers and developers can save significant time and costs through the consistent use of the latest AM technologies and get to market with products faster. Especially in this pandemic period, exactly such solutions were developed and manufactured by additive manufacturing in an extremely short time and could already be installed in the aircraft after only a few weeks.

As supply chains were interrupted due to the pandemic, local production became very important. Companies had to rethink and also look for local production possibilities without letting costs rise significantly. Additive manufacturing was and is a good bridging solution here. With AM technology, small quantities can be produced promptly and thus production downtime can be avoided. Of course, this requires a certified production solution, which requires consistent quality management and the latest manufacturing and measuring equipment. Additive Flight Solution has just invested in new technologies and staff to deliver economical and quality consistent solutions to the industry.

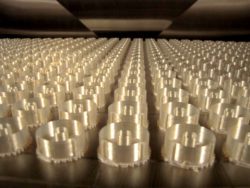

Small production series can benefit from AM. With technologies like the new SAF technology from Stratasys, parts up to 10.000 can be produced. Customers can avoid heavy initial investments because tooling cost can be skipped and the minimum order quantity is reduced significantly. This helps companies to keep a healthier cash flow as well.

We have setup a production facility and regional Headquarters in Singapore to meet the demands of aerospace MRO needs; by supporting the demands of additional decentralized production of certified aviation cabin interior parts.